Block Making Machine

Block making machines are designed to produce concrete blocks, paving blocks, styrofoam concrete blocks, curbstones, roof blocks, and a variety of special products and custom designs by using vibration and pressure at the same time.

According to your project budget and needs, Bess company offers the most suitable machine for you. Bess has exported more than 350 concrete block machines to many countries which have been a good investment for customers in this field up to now, and we have become one of the largest block making machine sellers in the European and Arabic markets and also in the Middle East countries as well.

Bess Company is located in Trabzon city in Turkey. Bess machines can produce almost any kind of concrete products like concrete blocks, paving blocks, curbstones, roof gutters, lego blocks, styrofoam concrete blocks and etc. Also besides these machines, Bess produces different types of molds for any type of block making machine with any brand. If you want to know more about this subject you can read more in ''what is a hollow block?''

With Bess concrete block machines, you can produce high-quality concrete products, Bess concrete block machines produce various products which are used to form the most spectacular buildings and walkways.

The Turkish block making machine is one of the most popular machines in the construction field. Because these machines are suitable for mass production of concrete blocks. These blocks are produced without any deformations and cracks. Depending on the quality of your machine it can be quite easy to produce these blocks. Bess is also an automatic block machine supplier to different countries.

Block Making Machine Price And Automation Level

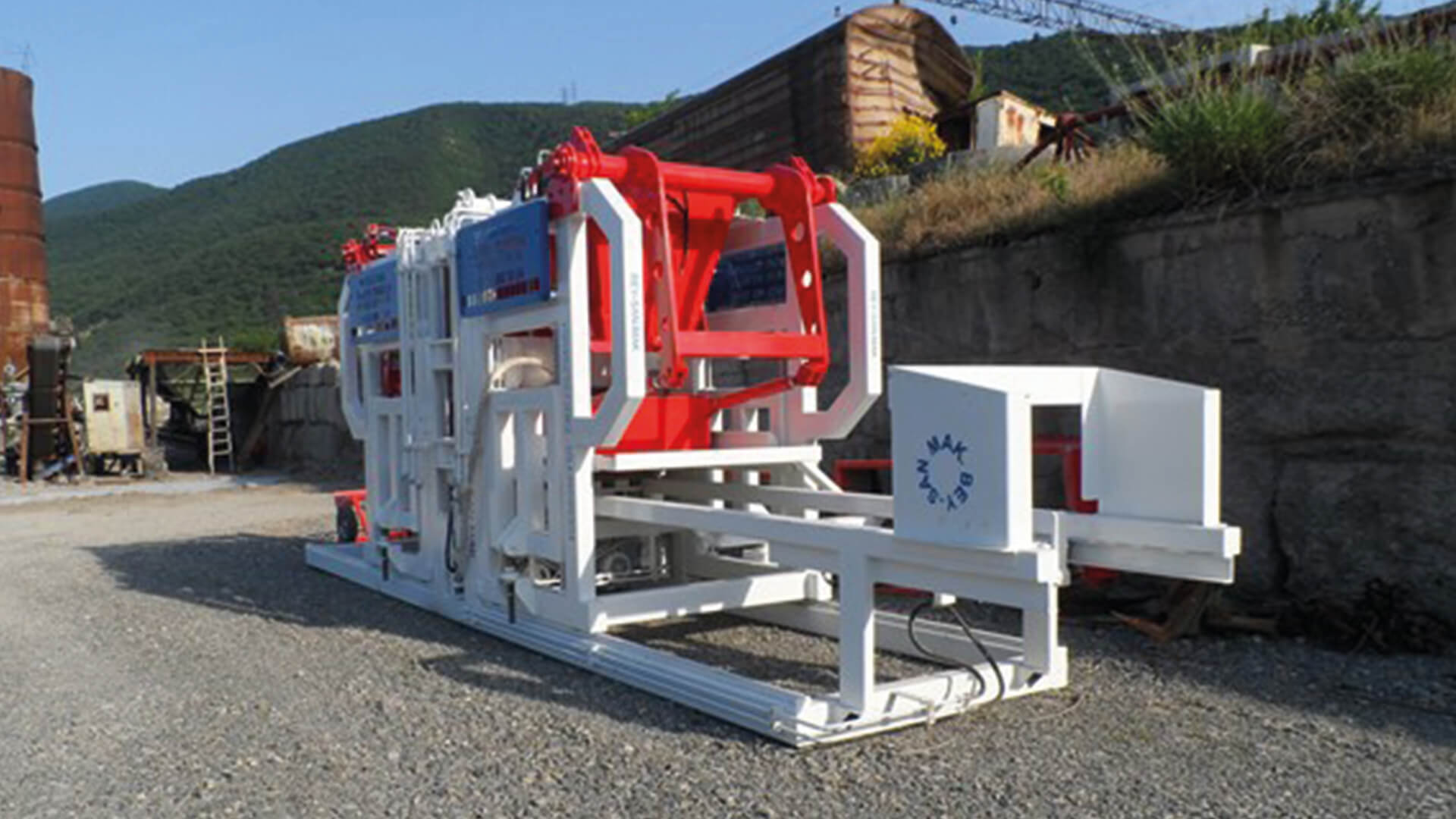

Bess company's policy is to produce the best concrete block making machines with premium quality and reasonable price. To achieve this goal only premium quality raw materials, metal sheets, and electrical components are used. For hydraulic equipment, only well-known German brands are used as well. For the power system, we use the Schneider brand to have maximum reliability. For the control system, we use Siemens PLC for maximum accuracy.

For automation, Bess offers three different options; below you can see the details. apart from the automation level Bess also offers different capacities for each one of the stationary and mobile machines. Different names of the machine are used to make you familiar with the names that the machine has. you can also read our articles ''concrete block making machine'' or ''brick making machine for sale''.

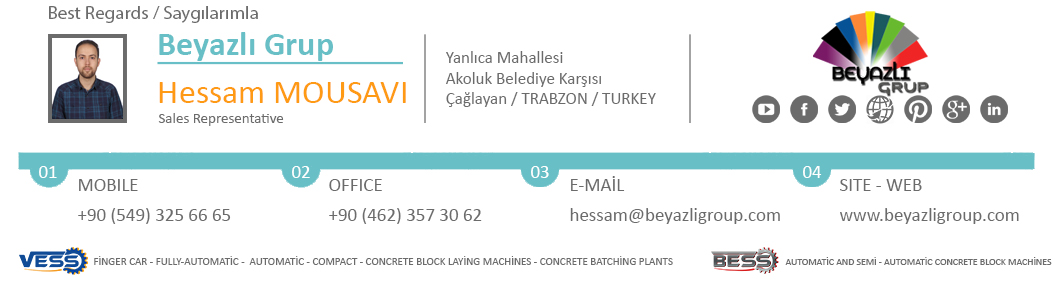

♦ Semi-Automatic Block Making Machine:

Bess offers this kind of automation for starters who have no experience and who want to produce concrete products with more workers. The price of this machine is lower compared to other automation levels. The semi-automatic block machine is suitable for countries with low labor costs.

This machine is suitable for countries with cheap lands and cheap labor costs. Countries like Ghana, and other African countries.

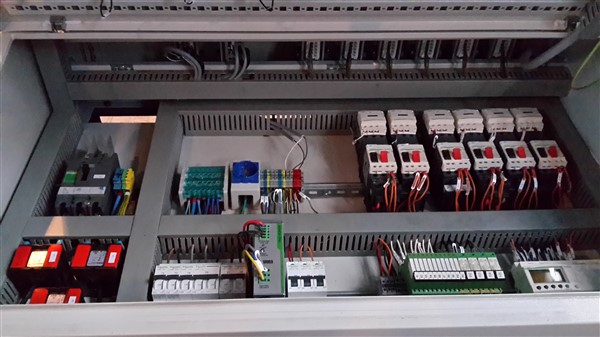

♦Automatic Concrete Block Machine:

Bess offers this kind of automation for the customers who have experience and want to produce any kind of concrete block products with fewer workers. In this machine, robots do some of the jobs instead of workers. The price of these machines is higher than the semi-automatic type because robots are used in the machine. If you need more information you can read the article Automatic Concrete Block Making Machine Price.

If you are living in countries like Norway, Denmark, Hungary, Poland, Serbia, or Kosovo this machine is a logical option for you.

♦ Fully Automatic Interlocking Brick Machine:

This kind of automation is for customers who want to produce any kind of concrete product with only one or two workers on their site. This is mostly recommended for countries with high labor costs. The price of a full-automatic machine is higher than the other options because robots do most of the job. The mistake rate and fault rate in these machines are less than the other options.

Block Making Machine Market

Our machines are of various types and capacities producing between 4.000- 24.000 standard hollow blocks in an eight-hour shift. The block making machines are capable to work 24 hours, which means you can produce hollow cement blocks in three shifts a day. Only heavy-duty machines are capable of working for 24 hours. If you want to see all our other machines, technical details and prices you can see our products.

If you have any questions about the machines please contact us directly or send us an email, we will respond immediately. The installation of the machines is for free at your plant. By machine failures, we guarantee to intervene domestically 48 hours or globally in 120 hours. The machine has two years of guarantee well.

Your 2 years guarantee starts after our technical team comes to your site, installs the machine for you, and teaches your operators how to operate the machine. An official certificate is also given to your operators after they are trained by our technical team.

Semi-Automatic Block Making Machine Features

Below you can see some features and advantages of the semi-automatic hollow block machine. The machine has one mortar hopper, and the machine is able to produce single-layer concrete paving blocks as well.

♦ The machine’s automation is the semi-automatic type.

♦ Daily capacity in an eight-hour shift is 4000 pieces of standard hollow blocks or 300 square meters of paving blocks.

♦ Possible to produce different types of stone products like curbstones.

♦ It’s easy to change the mold (By changing the mold, the machine will produce different shapes of concrete blocks).

♦ The interlocking brick machine is coming with the necessary equipment, and you can also buy additional parts for the machine when you need it.

♦Bess will provide the technical drawing based on your land dimensions, and with this document, you can easily prepare your own land.

♦ Totally 2 years of warranty for the hollow block machine and the parts.

♦ We can provide support when you face any kind of problem. For major problems, we can send our technical team for fixing the problems. It rarely happens due to the high quality of the machines.

Note:

The industrial name of the single-hopper machine is the hollow block machine.

The industrial name of the double-hopper machine is the paver block machine.

Concrete Block Mold

There are almost 600 different molds available for block making machines. Each mold has its special shape and dimension. You can almost produce all kinds of concrete products with these machines. These are the general products:

1. Hollow concrete blocks

2. Paving blocks

3. Tiles

4. Roof gutters

5. Lawn stones

6. Curbstones

7. Insulated blocks

You need to order your desired molds from the manufacturer's company. It usually takes 4 weeks to 6 weeks to produce a mold depending on its shape and size. The size of each mold differs according to the size of the machine. Bigger machines have bigger molds and of course, they produce more concrete blocks in each press.

If you also need Turkey concrete block mold prices or you need a reliable Turkish concrete block molds manufacturer you can always contact us.

High-quality molds are produced from Hardoax metal or ST52 metal sheets to have maximum strength again pressure and wear. The machining process is done by CNC machines to reach maximum accuracy. They are also hardened twice to reach maximum strength. Bess molds have a guarantee of 60.000 presses.

How To Start Your Block Making Business

To establish a block making plant, you need to have a minimum of 2000 square meters of land. You also need roofing for 1/3 of your land to place your machine in it. You need to provide aggregate, water, and cement for your plant as well. 3-phase power should also be provided by the net or a separate generator to power up the plant. The block making machine consumes around 20kw to 30kw of electric power.

For water, you will need a pump that comes with the machine or if there is tapping water available with an acceptable flow, it can be used instead of the pump. Adding water is done automatically by the machine in an automatic block making machine and it is added manually in the semi-automatic machines.

Consider in mind that when you choose a manufacturing company to buy your concrete block machine from, you should care about the price and quality. In some countries labor cost is high and as a result, the machine’s final price is high. In some countries, labor cost is too low but the raw materials used for the machine are low quality as well, but in some countries the labor cost is acceptable and the quality of the raw materials is high as well. So the final price of the machine is reasonable and the quality is acceptable as well.

Stationary Block Machine Working System

First, you need to prepare the mortar with the right ratio, usually, one unit of cement is added to four units of additives and sand. Then you need to add the right amount of water till the mortar becomes like a paste. This action is done in the mixer. Some stationary hollow block machines do the whole process of preparing the mortar automatically and some others do it semi-automatically.

Then the mortar is delivered to the hopper of the machine by a conveyor belt. The block making machine will take care of the rest of the job, first, the mortar is poured into the mold filler machine also called the mortar cart and the mold filler machine starts to fill the mold by going back and forth.

when the mold is filled the vibration starts to vibrate the mortar so the tiny space between sands can be filled and when it vibrates, the surface of the mortar shrinks. The mortar cart machine starts to fill the mold for the last time before the press starts its job.

Pressing takes place on the surface of the pallets with the bottom and top molds of the machine. After pressing takes action, the pallet is automatically delivered to the output of the block machine. Pallets are then delivered to the drying section. Delivering the pallets from the block making machine is optional. It can be ordered with handcarts or as an automatic. It depends on your budget and production capacity.

For more videos, you can also visit the BESS machine EN youtube channel.

Conclusion

With years of experience in this field, Bess company recommends you not to buy the cheapest or the most expensive concrete block machine but to consider all the characteristics and buy a premium quality machine at a reasonable price. You also need a concrete block manufacturing business plan to run your plant with the highest efficiency. You can contact us at any time in order to help you with your business.