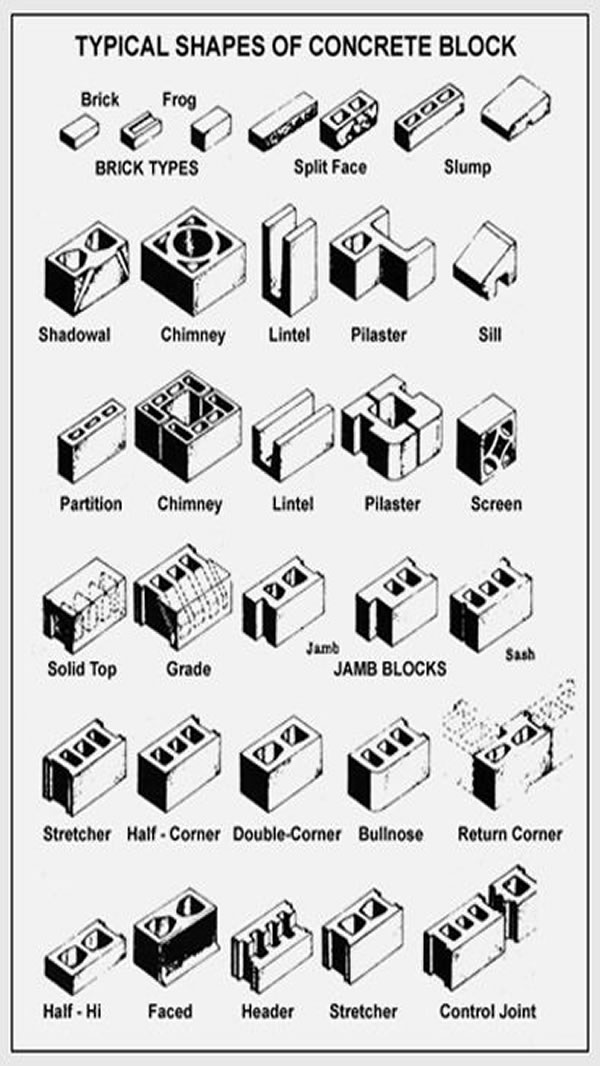

Concrete Brick

Concrete bricks also called concrete blocks are hollow or solid bricks that are made of concrete using vibration and compression. These blocks are produced by automatic brick making machines most of the time and they are available in many shapes and sizes. The most regular concrete brick is the hollow concrete brick with 20cm height, 40cm length, and 20cm width.

Concrete bricks have lots of advantages over other materials. They are lighter than the classic options so they reduce the total weight of the building.

Concrete bricks are also larger in size so the construction will be much faster and easier.

Concrete bricks are fireproof, so the main structure of the building will not be damaged after the fire. If you are interested in concrete brick production, you can read the original article on what concrete blocks are in general and in detail.

What Is A Brick Making Machine?

Brick making machine is a machine that produces concrete brick using mortar and mold. To produce these bricks, the pressure is applied to the mold by vibration.

Brick making machines are available in various shapes and sizes. There are generally two types of brick making machines

1. Mobile brick making machines

2. Stationary brick making machines

Mobile brick making machines are simple, cheap, and produce bricks on the ground so they do not need pallets but their capacity is low compared to stationary brick making machines. There are only a few options for molds for mobile brick making machines.

If you are interested in this type of machine you can original article brick laying machine.

Stationary brick making machines are available in different capacities and different automation levels. Stationary brick making machines are available from simple brick making machines with a low or medium capacity to fully automatic brick making machines with high production capacities. Based on the product that these machines produce they are also called hollow block machines and paver block machines.

Automatic Brick Making Machine

In an automatic brick making machine, most of the brick production steps are done automatically. The process that is done automatically is listed below:

1. Mortar preparation system: this consists of weighing and adding aggregate to the mixer, adding cement, adding water, and mixing them to have a homogenous mortar, and delivering it to the concrete hopper of the automatic brick making machine.

2. Transferring the pallets for the curing area: after the blocks are produced by the machine, the pallets are delivered to the loader robot. The loader robot stacks five pallets on top of each other and then the forklift delivers all five pallets to the curing area.

3. Product collecting system: after the products on the pallets are dried, the forklift transfers the pallets to the unloader robot which is located at the input of the automatic brick making machine. The unloader robot divides the pallets one by one, and the product collecting robot collects the bricks on the pallets and the pallet is again ready for production.

Consider that one operator is needed to operate the machine and one is also required to operate the forklift.

The quality of the equipment used at the level of automation is very important because if they fall into the faults your production will be stopped. Bess uses only German brands Siemens plc, Schneider contactors and relays, and Bosch hydraulic equipment for automation.

How Does An Automatic Brick Making Machine Work?

You need to fill the aggregate hopperof the automatic brick making machine, there is a weighing belt under the aggregate hoppers that weighs the aggregate, then it is delivered to the mixer. Water is added with a digital counter to the mixer and then the cement screw adds the cement to the mixer. The mixing system of the machine is automatic. There are also semi-automatic and fully automatic brick making machines available.

When the mortar is ready it is delivered to the mortar hopper of the automatic brick making machine.

In an automatic brick making machine, there are four joysticks that control the machine. The operator runs the production process and when the bricks are produced on the pallets, the automatic brick making machine automatically delivers the pallet out of the machine and towards the robot loader. The rest of the process is explained before.

Below you can see how Bess automatic brick making machine works. You can also visit the Bess youtube channel for more videos.

How Much Does A Brick Making Machine Cost?

Speaking frankly, an automatic brick making machine is not always the best choice for your brick making plant. There are some criteria you should consider before choosing your machine.

Automatic brick making machines are cheaper than fully automatic machines and more expensive than semi-automatic versions. But each one of them has its pros and cons. If you are living in a country like Ghana, Uganda, Kenya, Somalia, Ethiopia, or other countries with low labor costs and cheaper lands Bess suggests you choose semi-automatic brick making machines because they are easier to start with and cheaper than the other options.

If you are living in a country like the United Kingdom, USA, Canada, Australia, News land, France, and other European countries, Bess suggests you choose an automatic brick making machine or a fully automatic machine for your plant because of the advantages that the automatic types have over the semi-automatic machines.

| Machine Name | Automation Level | Capacity In Eight Hours | Installation | Price |

| PRS-400 | Semi-automatic | 4000 Pieces of standard blocks | Included | 47200 USD |

| PRS-800 | Automatic | 8000 Pieces of standard blocks | Included | 97400 USD |

Conclusion

To choose the best brick making machine for your plant you need to consider some factors. The first one is labor cost; If the labor cost is not high in your country then you do not need to choose more expensive machines, instead of automatic brick making machine you can choose a higher capacity semi-automatic machine.

The second factor is the price of land. If the land is available in your country, you do not need to limit your choice of automatic brick making machine.

The third factor is the budget for your project. Consider that you should not spend all your budget on the machine, you need to save a piece of your budget for land preparation, buying cement and aggregate, and transportation of the machine to your country.

The fourth factor is the country you are installing your brick making machine in it. You need a suitable concrete block production business plan based on your machine and your country. With over 15 years of experience in this work, Bess prepares your concrete block manufacturing business plan with your machine free of charge. Contact the English department for more information.