Brick Making Machine

Generally, a brick making machine is a machine that produces bricks using electrical vibration and hydraulic pressure. These machines are produced in different types with different automation levels and capacities.

Brick making machines are one of the most crucial machines in the construction industry because all the hollow blocks, solid blocks, paving blocks, and curbstones that are used in the construction field are produced by these concrete brick machines.

Brick-making machines are manufactured in numerous countries, offering various systems and price ranges. Despite these differences, the overall process remains largely consistent. The process involves applying pressure to concrete mortar, and compressing it to create various shapes.

Here is a step-by-step breakdown of the brick-making machine's operation, highlighting its details:

Brick Making Machine Capacity

It is essential to understand the meaning of brick making machines' capacity because it's an international standard that every manufacturer builds its machine based on it. The brick making machine's capacity is determined by the number of standard blocks it can produce in a single cycle.

Understanding the meaning of capacity is crucial when it comes to brick making machines, as it serves as an international standard that guides manufacturers in designing their machines. The capacity of a brick making machine is determined by its ability to produce a specific number of standard blocks within a single cycle.

In this context, the standard concrete brick we refer to has dimensions of 20cm in width, 40cm in length, and 20cm in height. This standard block serves as a benchmark for determining the machine's capacity. If you need more information about the products you can read our articles "What hollow concrete block is in general and in detail" and "What is Hollow Block?".

Brick Making Machine Different Names

Brick making machine has different names based on the bricks it produces.

When this machine produces hollow blocks, it is called a hollow block machine.

It is called a concrete block machine when it produces solid concrete blocks.

When you use interlocking molds in your production line, it is called an interlocking brick machine.

Also, some customers order their machine as a double-hopper machine, this machine is generally called a paving block machine because it can produce double-layer paving bricks.

As you see, there are different names for this machine so don't get confused when they are used interchangeably.

Bess company Offers Different Brick Making Machines For Different Projects

Bess offers different brick making machines for different budgets and projects. Depending on your demand and your country you can choose the most suitable machine. Our engineers also provide you with technical information and details of your local market to help you choose the best machine for your business.

Bess also provides you with the most suitable concrete block manufacturing business plan to keep you up among your rivals in this business.

Below you can see the different choices to choose your machine:

1. Mobile brick making machine:

This is the smallest brick making machine and the cheapest one as well. Most of the process is done manually in this offer. So, you need more workers compared to other machines. The mortar preparation, transferring mortar to the machine, and collecting the dried blocks are done manually in this system.

It also has the advantage that it doesn't need pallets to produce bricks. The mobile brick laying machine lays the bricks on the ground.

Note that mobile bricklaying machines can't produce paving bricks, and also, the available mold shapes are limited. The mobile brick machine's capacity is 2250 to 3500 pieces of standard bricks in an eight-hour shift.

2. Semi-automatic stationary brick making machine:

The stationary brick making machine is suitable for small projects that require higher production capacity in their production line. These machines have different capacities. The smallest brick making machine can produce 4000 pieces and the biggest can produce 10.000 pieces of standard blocks in an eight-hour shift. For higher capacities, Bess offers automatic machines because it is easier to handle the production by robots.

This machine is also available in both single-hopper and double-hopper. Based on your market demand, You can order the suitable one for your plant.

3. Automatic stationary brick making machine:

Developed countries mostly prefer automatic brick making machines because labor costs are high in developed countries. They prefer robots to do the job and reduce plant costs as low as possible.

This also reduces the final price of the bricks as low as possible to keep up with their rivals. The machine's price may look a little bit high in the beginning. Still, it is more beneficial and economical for developed countries in the long term.

4. Fully automatic brick making machine:

Full automatic brick making machines are operated completely automatic. You only need to push the machine's start button and a forklift driver to handle the products. Their product capacity usually starts from 10.000 pieces of standard blocks in an eight-hour shift and the biggest one can produce 24.000 pieces per shift.

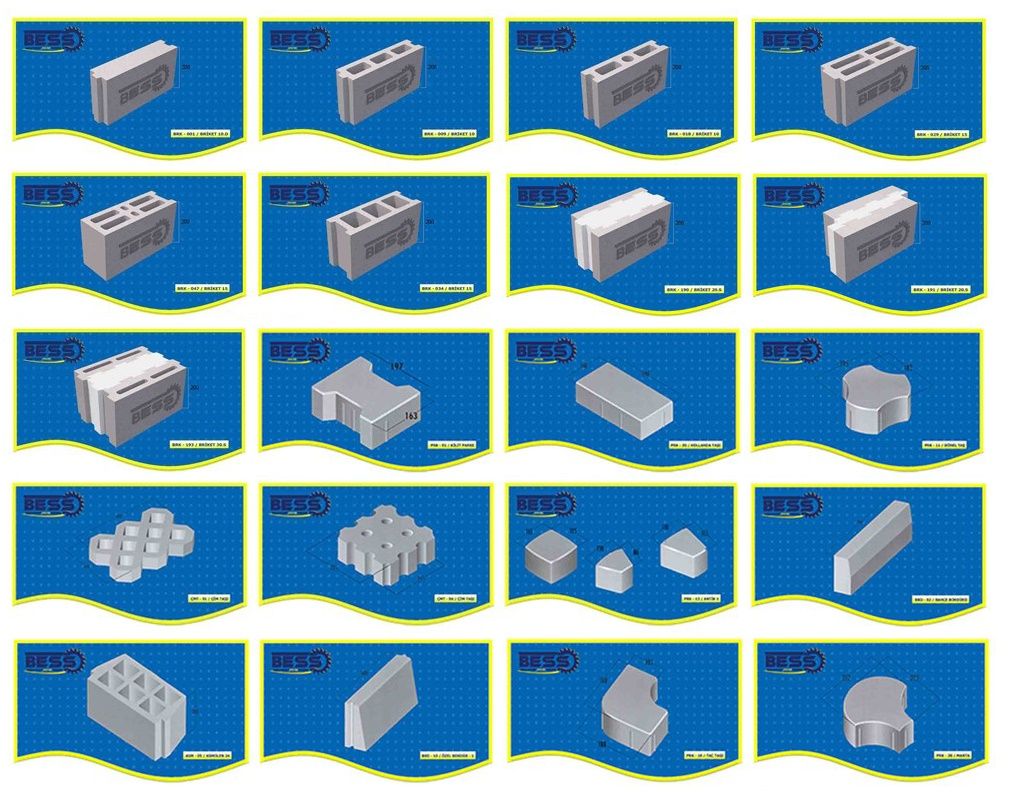

Different Concrete Block Shapes

As described in this article, this machine has different names based on its production. There are almost 600 different molds available for brick making machines. For our classic machines, the height of the product must be between 5cm to 30cm and for compact series, the product's height needs to be between 2cm and 25cm.

Below you can see the general list of the products.

- 1. Hollow concrete blocks

- 2. Solid concrete blocks

- 3. Paving blocks

- 4. Curbstones

- 5. Asmolen blocks

- 6. Styrofoam blocks

Consider that there are different additives available in the market to add to the concrete mortar used to produce these blocks. Each of these additives adds a feature to the mortar. You need to consider your market demand to choose the right additive for your business as well.

You can visit the Bess mold gallery for mold samples.

How To Choose The Right Brick Making Machine For Your Business

This part is the most critical part of your project. You need to consider every detail of the machine to choose the right machine.

First of all, you need to consider vibration force and hydraulic pressure. These two factors are the most important factors because they directly affect your product's quality.

Secondly, you need to control the raw materials used to manufacture the machines. It is vital because if the raw materials like metal sheets are high in quality, they will keep your machine together for a long time

Thirdly, you need to check which brands the manufacturer uses for the electric and hydraulic parts. This is very important because it determines the fault rate of your machine. Well-known German brands are the best choice.

Brick Making Machine Price

The price of the standard machines is written below. For more information, you can call our English department. The English department's contact info is at the end of this article.

| Machine Name | Plant Price | Description |

|---|---|---|

| PRS-400 | 53,770.00 € | Single-hopper semi-automatic |

| PRS-402 | 74,820.00 € | Double-hopper semi-automatic |

Brick Making Machine Total Price

There are some unnecessary items in the proforma that you need to cross. For example, you don't need to order pallets from the manufacturer's factory. You should provide them locally, this way you will save the transportation cost and don't need to pay for pallets in euros or dollars.

It would help if you also chose a cheaper machine than your total budget because you are going to pay for aggregates and preparing your land. Bess suggests you not spend your whole budget on the machine.

The factory you choose to buy from shouldn't be too far from you if you are buying big machines that occupy a few containers. The total freight cost will be too high this way. Buying a big machine from a far country is only logical if the quality meets world standards. If there are no manufacturers in your country, you can choose Turkish brick making machine manufacturers. They offer high-quality machines at reasonable prices.

Related keywords to this article:

- brick machine

- bricks machine

- brick making machine for sale

- brick maker machine

- concrete bricks machine

- bricks making machine

- bricks manufacturing machine

- interlocking brick making machine

- brick manufacturing machine

- automatic brick making machine

Conclusion

Generally, the brick manufacturing business is very prosperous, but you need to be careful to make the right choices. This article discussed some important items to help you establish your concrete brick making plant. You can contact our English department to learn more details.