Automatic Concrete Block Making Machine

Bess is a Turkish Factory that offers a high-quality range of Automatic Concrete Block Making Machines. Bess machines are manufactured using high-quality systems and cutting-edge technology with the help of skilled professional engineers.

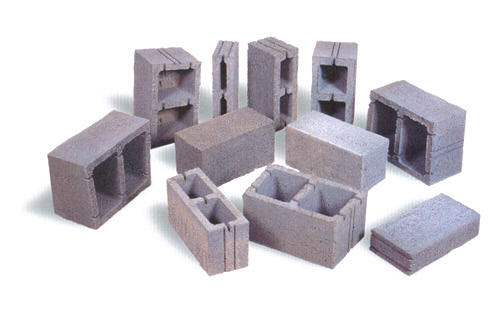

The offered machine produces different types of concrete blocks like Solid blocks, Hollow blocks, Paver blocks, etc. We offer Bess Automatic Concrete Block Making Machines in different capacities according to different needs to meet the various needs of our clients at the best prices.

- Robust construction

- Long operational life

- Precisely designed

- Easy to operate and user friendly

- Different production capacities available

- Different mold choices for production line

We are producing concrete block machines with different capacities and different technical specifications. Our products are reliable and the best for customers that want to produce brick blocks, paving blocks, garden blocks, concrete blocks, etc. There are so many companies that produce or design machines the same as our machines but it’s not the same quality. Our production is divided into semi-automatic, automatic, and fully automatic machines.

We are producing concrete block machines with different capacities and different technical specifications. Our products are reliable and the best for customers that want to produce brick blocks, paving blocks, garden blocks, concrete blocks, etc. There are so many companies that produce or design machines the same as our machines but it’s not the same quality. Our production is divided into semi-automatic, automatic, and fully automatic machines.

Our range of machines is available at the market with the most suitable price for the automatic concreteblock making machine both in the African and Asian markets for small investors and for European investors for big projects with high production capacity.

Features Of Automatic Concrete Block Making Machine

1. Control system is automatic:

The loader and unloader robots are working automatically and a forklift delivers the pallets to the curing area. After they are dried, the forklift delivers them back to the unloader robot so the blocks can be collected and ready for the market.

2. Production capacity is 120 pallets per hour

Depending on the shape that you are producing, the machine can produce between 100 and 150 pallets per hour.

3. Weight is between 6500kg and 11000kg

Small machines are lighter due to their smaller structure and smaller molds and the bigger machines have a bigger chassis and bigger body frame.

4. The machine is very fast and has a high production capacity

5. Easy installation:

The installation is done by our team. After you purchase the machine and it is delivered to your site, our technical team will come and install the machine for you, run test productions, and train your operators to use the machine properly. The guarantee period starts after the installation.

Consider that the price of the concrete block machine differs based on 3 factors

1. The automation level.

2. The capacity of the machine.

3. The equipment that the customer chooses for the machine.

If you are interested to know the prices, you can read the article that we have prepared ''Concrete block machine: description and price''.

The prices in this article are prepared based on the three factors that are mentioned above.

Concrete Block Machines Automation Systems

After your machine is installed you need to fill the aggregate hopper with aggregate, the silo with cement, and provide water for the mixer.

When you start the machine, the machine starts to add the aggregate, cement, and water with the right ratio to the mixer. The mixer mixes the materials to form a paste-like mortar. The mortar is then delivered to the hopper of the machine.

With the help of the operator, the machine starts to produce concrete blocks. For operating the machine you can also choose fully automatic so the machine operates without an operator or you can operate the machine with one operator who controls a total of 5 movements.

After the blocks are produced on the pallets, they are stacked on top of each other by the loader robot. They are then delivered to the curing area by forklift. This robot is also called the stacker robot.

The next day when the blocks are dried the forklift takes the pallets to the unloader robot where they are divided one by one and their blocks are collected for sale.

This is the general working system of the automatic concrete block making machine. You can also contact us if you have any questions. We have also included prices in Concrete Block Machine For Sale for the readers.

Building Materials Production

Semi-automatic, Automatic, and full-automatic machines offered by Bess can be used for producing all kinds of building materials such as concrete bricks also called solid blocks, concrete blocks also known as hollow blocks, interlocking paving blocks, curbstones, insulated blocks, and chimney blocks. The picture below is a few sample products of Bess concrete block machines.

It's durability, corrosion resistance, and elevated performance is what makes Bess machines one of the most popular products. Bess automatic concrete block making machine is highly demanded and appreciated, especially in Asian Countries. Our designed automatic concrete block making machine are widely appreciated in the construction industry.

Bess automatic concrete block making machine is extensively used thanks to its compact design, rigid construction, and excellent mixing of building material.

Below you can see the video of the automatic concrete block making machine. You can watch more videos on our youtube channel Bess Machine En.

The difference between single-hopper and double-hopper automatic concrete block making machine

Both machines can produce all the available shapes that the customer asks but the difference is that the double-hopper concrete block making machine can produce double-layer paving blocks, this is especially used for paving blocks.

Double-layer paving blocks can have better quality on the surface and also with finer aggregates for a smoother surface. It is also possible to use color pigments in the mortar to produce colored paving blocks. Below you can see a double-hopper automatic concrete block making machine.

You can read everything about this machine in our article paving block machine.

You can also read the details about single-hopper machines in the main article hollow block machine.

Conclusion

To buy the right machine for your plant and produce the product based on your market demand you need to have the general information and know the standards as well. You also need to have a concrete block manufacturing business plan for maximum efficiency. You can contact our English department to get the best offer based on your budget and your project details as well.