Hollow Blocks Business Plan

The hollow blocks business plan has gained immense popularity in recent times, not just within our country but also across the globe, particularly among those aspiring to establish a profitable business in the construction industry. Presently, the market for building materials is witnessing significant growth and there are new types of concrete blocks that are more efficient and cost-effective.

In this article, we will present a comprehensive and profitable business plan for the production of hollow blocks. It is a complementary piece to the main article on hollow block machines, which highlights the technical and operational aspects of concrete hollow blocks and the machines used in their production. By referring to this plan, prospective private developers or entrepreneurs can effectively select the required equipment based on their specific requirements and goals.

When establishing a business in this field, entrepreneurs can expect to encounter minimal complexities, as the production technology is straightforward, and the finished product can easily obtain mandatory certifications. This advantage leads to reduced investments and reduces challenges associated with marketing and product promotion to a minimum. The concrete block machine serves as the primary equipment for manufacturing various building materials from concrete. These materials are hollow blocks, solid blocks, styrofoam concrete blocks, paving blocks, curbstones, and other decorative products.

The Hollow Blocks Business Plan Includes The Following Items

* Market analyses for the concrete products

* Business plan for the production process

* Purchasing concrete hollow blocks machine

* Production technology

* Calculation of profit of the enterprise

You especially need to answer these questions for this business. Why do you choose this particular line of activity? What is the advantage of a hollow blocks production business? Concrete hollow blocks are a fairly popular material in construction. Demand for it increases significantly during the construction season. This is due to the following factors:

- Affordability: Hollow blocks have a lower price compared to other construction materials, making them highly demanded for the construction of cost-effective country houses.

- Lightweight nature: Hollow blocks, depending on the raw materials used, are lighter than alternative construction materials. This advantage reduces the total weight of the building.

- Environmentally friendly: These special concrete hollow blocks are manufactured using only cement, sand, water, and various additive materials, without the inclusion of harmful chemicals. This ensures their environmental friendliness.

- Effective insulation: With low thermal conductivity, hollow blocks contribute to reducing heating costs in houses or rooms by approximately 20-30%. This eliminates the need for additional expenses on heat-insulating materials.

From a business point of view, the production of hollow blocks is profitable due to the availability of a rich raw material base in any country, a good choice of domestic and foreign equipment, and a simple production technology.

Block Making Machine Details

For producing good quality hollow blocks, you need to purchase any kind of high-quality concrete hollow blocks making machine.

What equipment will be needed for the production of hollow blocks :

- Hollow block making machine

- Concrete mixers

- Aggregate hopper for raw materials such as cement, sand, water, and additives

- Conveyor belts for transferring the materials into the mixer

- concrete block mold

- supplying raw materials, water, and cement

Production Process Of Concrete Hollow Blocks

The production process of concrete hollow blocks consists of three main stages:

- Mixture Preparation: In this initial stage, different raw materials are combined and mixed in a concrete mixer to create mortar. The mixer blends the ingredients thoroughly to ensure a homogeneous mixture.

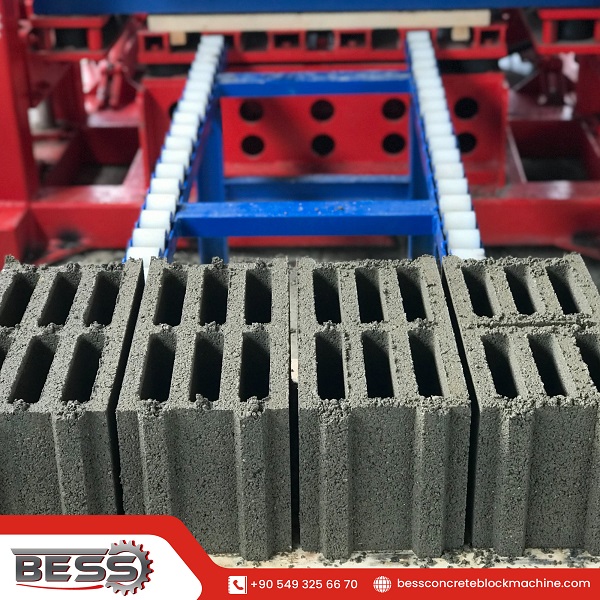

- Block Production: The second stage involves the actual production of the blocks. This is achieved using either semi-automatic or automatic concrete hollow block machines. These machines are capable of efficiently shaping and forming the blocks according to the desired specifications.

- Curing and Storage: The final stage entails curing and storing the produced blocks. Once the concrete hollow blocks are ready, they are transferred to a designated area for the curing process. After curing, the blocks are then stored until they are ready to be transported or used in construction projects.

After thoroughly mixing the mixture, it is important to pour it into the machine and activate the vibration and pressure. This ensures that the mixture is evenly distributed within the molds. As the concrete shrinks, additional portions of the mixture should be added until the molds are completely filled. Once the concrete has sufficiently shrunk, the molds can be removed, leaving the finished blocks on the pallet or a suitable surface. At this stage, a new batch of mixture can be poured in the molds.

Drying the blocks needs to be given a separate time: the first 24 hours the blocks dry as they were left after the machine. During drying, they sometimes need to be moistened with water, like any concrete product. After a day, the blocks are turned on their side and dried for another 24 hours. After 2 days, they can be stacked on pallets. further details are provided in brick making machine article. also, the prices of the machine are included.

Curing the blocks requires a separate period of time. Initially, the blocks are left to dry for the first 24 hours in the same position as they were left after the molding process. During the curing period, it may be necessary to occasionally moisten the blocks with water, as is common for concrete products. After one day, the blocks are collected from the pallets and dried for an additional 24 hours. After a total of two days, the blocks can be stacked or sold. More detailed information can be found in the brick making machine article, including pricing details.

When developing a hollow blocks business plan, a crucial decision arises regarding the choice of the hollow blocks machine to purchase. In our company, we specialize in manufacturing and currently offer a range of machines designed to cater to aspiring entrepreneurs entering the hollow blocks business. Our machines provide different options, ensuring that customers can select the most suitable one for their needs.

All of our machines possess the capability to produce a wide variety of concrete stone products, including concrete hollow blocks, paving blocks, curbstones, and more. By simply changing the mold, it becomes possible to manufacture different types of concrete stone products. As demonstrated, one of our automatic concrete hollow blocks machines showcases remarkable versatility by being able to produce nearly all kinds of concrete stone products.

As you embark on your hollow blocks business journey, our company stands ready to provide the necessary machinery, allowing you to explore diverse product offerings and seize opportunities in the market.

If you need to produce double-layer paving blocks with color, you will need double-hopper block making machines. This machine is called a paving block machine and they are categorized differently. These machines are a little more expensive than normal machines. you can read further details in its own article paving block machine.

The Advantages Of The Hollow Block Making Machine

* We are using high-quality materials for the concrete block machine.

* According to your demand you can buy any kind of machine-like full or mini plant, for each machine which we are producing in our company.

* We have different automation for the machines, semi-automatic or automatic.

* All machines are capable to produce almost all kinds of concrete stone products just enough to change the mold.

* High productivity - the machines can produce concrete hollow blocks, paving blocks, curbstones, and others.

*For more videos you can visit our youtube channel Bess Machine En.

Conclusion

It is strongly advisable to invest in high-quality hollow block machines when entering the hollow blocks business. By acquiring a reliable and reputable machine, you can ensure the production of concrete stone products without any deformations or cracks. If you choose to purchase any type of hollow block machine, it grants you the flexibility to manufacture various kinds of concrete stone products.

For more comprehensive information regarding our machines, we encourage you to reach out to us. We are readily available to provide all the necessary details, including technical specifications and pricing information. Our website also serves as a valuable resource where you can explore the range of machines we offer. As you embark on your hollow blocks business plan, rest assured that we are committed to assisting both new and experienced customers in finding the most suitable hollow block machine. The hollow blocks business presents itself as an ideal venture for individuals seeking a profitable and fitting opportunity.