Concrete Block

A concrete block refers to a block that is constructed using concrete material.

To enhance the quality of these blocks, it is essential to apply vibration and force during the production process, ensuring that the mortar is thoroughly compressed. Concrete blocks encompass various types, and here are a few examples for reference.

-

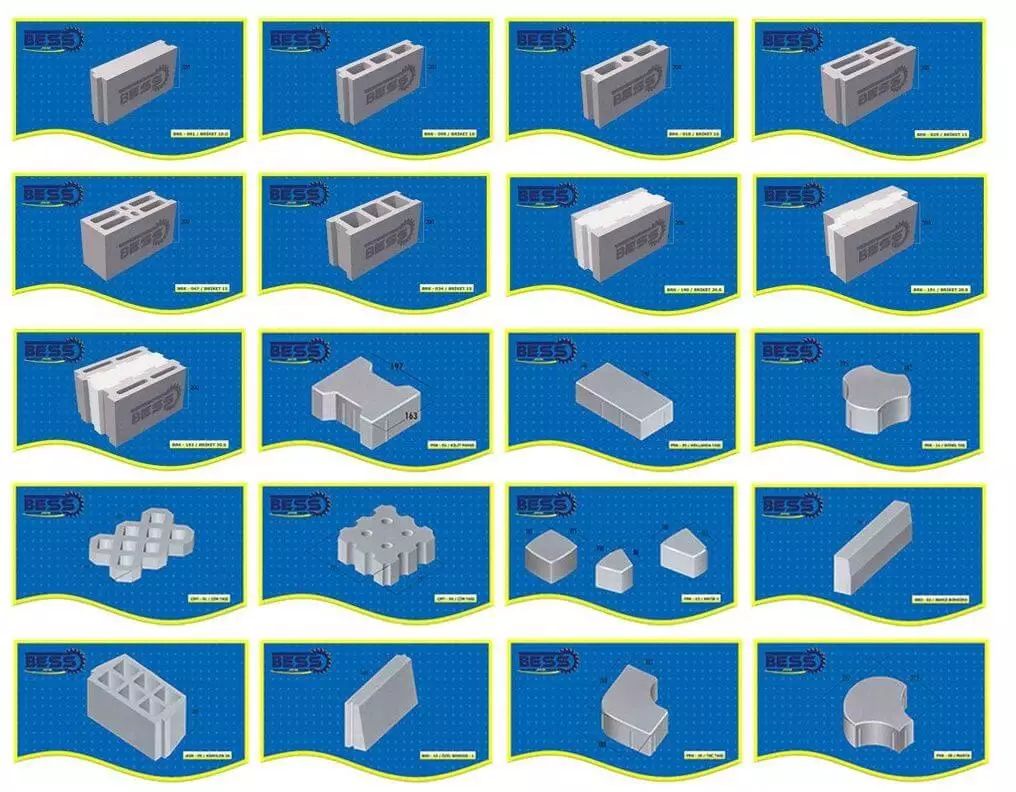

Hollow blocks with different shapes and sizes.

-

Solid blocks with different shapes and sizes.

-

Curbstones in different shapes and dimensions.

-

Paving blocks with different shapes, sizes, and colors.

-

Grasscrete blocks (also called lawn stones).

-

Concrete gutters also known as roof gutters.

-

Lego concrete blocks

-

Styrofoam concrete blocks

-

hollow floor blocks also called Asmolen blocks

Concrete is a substance that is present in all the mentioned items, but you might be wondering about its definition. Concrete is a composite material that comprises aggregates, water, and Portland cement, typically in powdered form. These components are combined in varying proportions according to specific standards for the mixture ratio. Moreover, admixtures are available to incorporate additional functionalities into the concrete mixture, allowing for customization and enhanced characteristics.

It's important to note the distinction between additives and admixtures in the context of concrete. Additives are incorporated into cement during its manufacturing process to impart new properties, while admixtures are introduced during concrete mixing to achieve specific features.

The choice of aggregates used in concrete production can vary depending on the country. Commonly used aggregates include limestone, shells, chalk, marl, shale, clay, slate, blast furnace slag, silica sand, and iron ore. For further information on this topic, you can refer to the Concrete Network. Additionally, our article titled "what hollow concrete block is in general and in detail" provides in-depth insights into hollow concrete blocks.

Concrete Block Manufacturing Process

The process of manufacturing concrete blocks involves several steps, which can vary depending on the system that is going to be used. These systems can be categorized as manual, semi-automatic, automatic, or full-automatic, depending on factors such as your location, labor costs, land prices, and budget. Here is a brief overview of these different production processes for concrete blocks.

1. Manual Concrete Block Manufacturing Process:

The manual method is the simplest and cheapest way. It primarily requires molds, where the concrete mixture is manually mixed and poured. However, the manual method lacks vibration and high pressure, resulting in lower-quality concrete blocks.

Due to the manual mixing process, it becomes challenging to achieve consistent ratios each time, affecting the overall quality of the final product. Additionally, the manual method is time-consuming as it relies solely on manual labor. Consequently, this method is no longer recommended as it lacks industrial advantages and efficiency.

2. Semi-automatic Concrete Block Manufacturing Process:

In the semi-automatic concrete block manufacturing process, a machine known as a concrete block machine is employed. This machine features molds where the blocks are produced under the application of pressure and vibration. The utilization of hydraulic pressure and vibration in this process enhances the quality of the final product, surpassing that of manual production.

However, it's worth noting that the mixing process is still conducted manually, leading to potential variations in the concrete ratio with each batch. Furthermore, the pallets produced by the machine require manual handling using hand carts, and the production process necessitates the involvement of three workers. Therefore, compared to other production methods, a higher number of workers is required.

If you have a limited budget and operate in a country with low labor costs and inexpensive land, the semi-automatic concrete block manufacturing process presents itself as an optimal choice for your business.

3. Automatic Concrete Block Manufacturing Process:

The automatic concrete block manufacturing method has gained significant popularity, as reported by our sales department. One key advantage of this method is the automatic preparation of mortar, ensuring consistent quality over time. The precise ratio of ingredients is maintained consistently, resulting in reliable mortar quality.

In the production process, robots play an important role, reducing the need for manual labor. Instead of using three handcarts, a forklift is employed to handle the production efficiently. Moreover, cement is stored in a cement silo and automatically added to the mixer, streamlining the process further. As a result, the number of workers required in your plant can be reduced. It is important to note that the machine is operated by an operator in this method, overseeing the overall operations.

4. Full-automatic Concrete Block Manufacturing Process:

In the automatic concrete block manufacturing method, an operator is required to operate the machine. However, in the case of a full-automatic concrete block machine, the machine operates automatically without the need for continuous human intervention. This design is particularly well-suited for developed countries where labor costs are high and land is expensive, as it allows for increased efficiency and cost-effectiveness in production.

Concrete Block Machine

There are different types of concrete block machines available in the market. Some of them are mobile and some of them are stationary. There are also different automation levels for the machines as well.

This article is about the concrete block production process so machine details are not discussed here. If you are interested in learning more details about concrete block machines you can read ''Brick Making Machine''.

Consider that to choose the right machine for your plant choosing the cheapest machine is not wise at all. You need to consider technical info like pallet size, hydraulic pressure, power consumption, and vibration force to choose the best machine. Bess offers you high-quality concrete block machines with different capacities and automation levels. Below you can see the concrete block production process done by our semi-automatic machine. You can access more videos through our youtube channels BESS machine EN.

How To Produce Concrete Blocks

To produce concrete blocks you need to provide your plant with raw materials like aggregate, water, and Portland cement. Then you need to mix them together to have a homogenous creamy mixture. There are different mixture ratios available based on your country's standards and aggregate availability. Also based on your machine choice it is done manually or automatically.

After you prepare the mortar it is time to feed it to the machine. Usually, it is done by conveyor belts. Then the machine takes care of the rest. the mortar is first poured into the machine aggregate hopper then it automatically feeds the mortar to the molds. When the mold is filled with mortar it is time for the hydraulic press to do the compressing. The vibration also helps the hydraulic system to compress it in the best possible way.

After the concrete blocks are shaped over the surface of the pallets, the machine leads the pallet toward the output of the machine. Now it depends on your machine if it is semi-automatic it is delivered to the curing section by handcarts. these machines are also called hollow block machines.

This process is the same in paver block machines too. the only difference is that the paving block machines have a second hopper to apply different colors to the surface.

If your concrete block machine is an automatic machine then first, 5 pallets are stored on top of each other and then they are taken by a forklift and delivered to the curing section.

If buying land costs too much in your area then it is better to choose the automatic system to save land for the curing section up to 5 times.

Concrete Block Manufacturing Daily Capacity

Each day consists of three shifts and each shift is eight hours. It is easier to discuss the capacity in each shift so there won't be any confusion.

Depending on the concrete block you are producing, the capacity of your concrete block manufacturing plant is different. Usually, paving block production capacity is discussed in square meters and the hollow blocks and solid blocks are described in numbers. The concrete block machines offered by Bess can produce 4000 pieces of standard blocks (20cm width x 40cm length x 20cm height) or 300 square meters of paving blocks in eight hours.

Conclusion

To produce the concrete blocks based on your market demand and local availabilities you need to choose the right machine and a suitable concrete block manufacturing business plan. Bess engineers can help you in every step of this business. All you need to do is to contact us.