Hollow Blocks, Solid Blocks, And Concrete Blocks In Different Types And Sizes

As you probably know, concrete blocks are mainly classified into two (2) types depending on the structure, shape, size, and manufacturing processes. These two types of concrete blocks are:

- Solid Concrete Blocks

- Hollow Concrete Blocks

Concrete blocks are produced in several dimensions and shapes. Concrete blocks are more resistant to natural disasters. In general, the hollow block walls are built with steel rods, cement, gravel, and other additional materials.

In order to manufacture concrete blocks such as hollow blocks, paving blocks, curbstones (or Kerbstones), etc. it is necessary to have a concrete block machine. The concrete block machines work with molds. By changing the mold you can produce the shape that you need.

Depending on the market demand and other factors like labor cost and land prices you can have a semi-automatic, automatic machine, or a fully automatic concrete block machine. If you need details about the machine you can read the article related to them ''Brick Making Machine''.

Solid Concrete Blocks

A solid concrete block, often referred to simply as a "solid block," is a type of construction material made from concrete. It is a rectangular or square-shaped block with a uniform composition throughout its entire volume. Solid concrete blocks are manufactured by casting a mixture of cement, sand, and aggregates into molds and allowing it to cure and harden.

Unlike hollow concrete blocks, which have voids or empty spaces within them, solid concrete blocks do not have any hollow spaces. This makes them denser and more substantial, providing greater structural integrity and load-bearing capacity. Solid concrete blocks are commonly used in various construction applications, such as building walls, foundations, and other load-bearing structures where strength and durability are essential.

Hollow Concrete Blocks

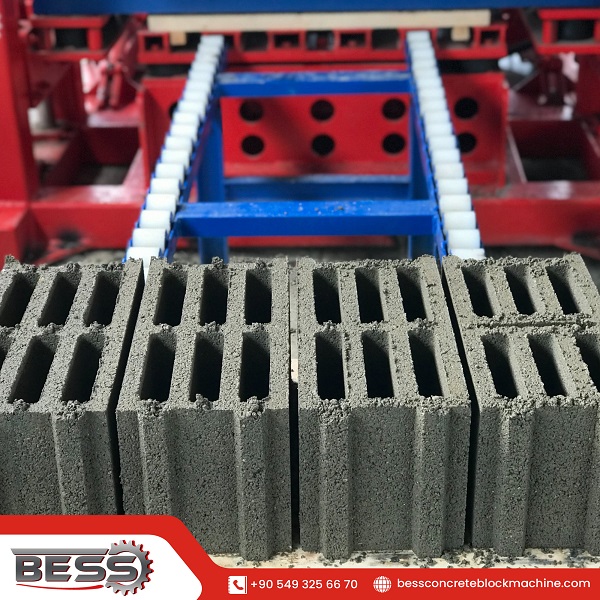

The holes occupy between 25-50% of the total volume of the block. Hollow concrete blocks are used as conduits for electrical wiring, plumbing pipes, and HVAC piping. Due to the hollows, the thermal and sound insulation properties of these bricks are very good, and they also require less concrete mortar or plastering compared to solid blocks. They are lightweight blocks and easy to install.

Hollow concrete blocks find extensive use in the construction industry and are composed of the same aggregates as solid concrete blocks. As the name suggests, these blocks feature cavities that reduce the total weight of the blocks.

The cavities typically occupy a range of 25-50% of the block's total volume. Hollow concrete blocks serve as channels for housing electrical wiring, plumbing pipes, and HVAC conduits. Thanks to these hollow spaces, these blocks exhibit commendable thermal and sound insulation properties. Additionally, they require less concrete mortar or plaster when compared to solid blocks. With their lightweight nature, these blocks are also convenient to install.

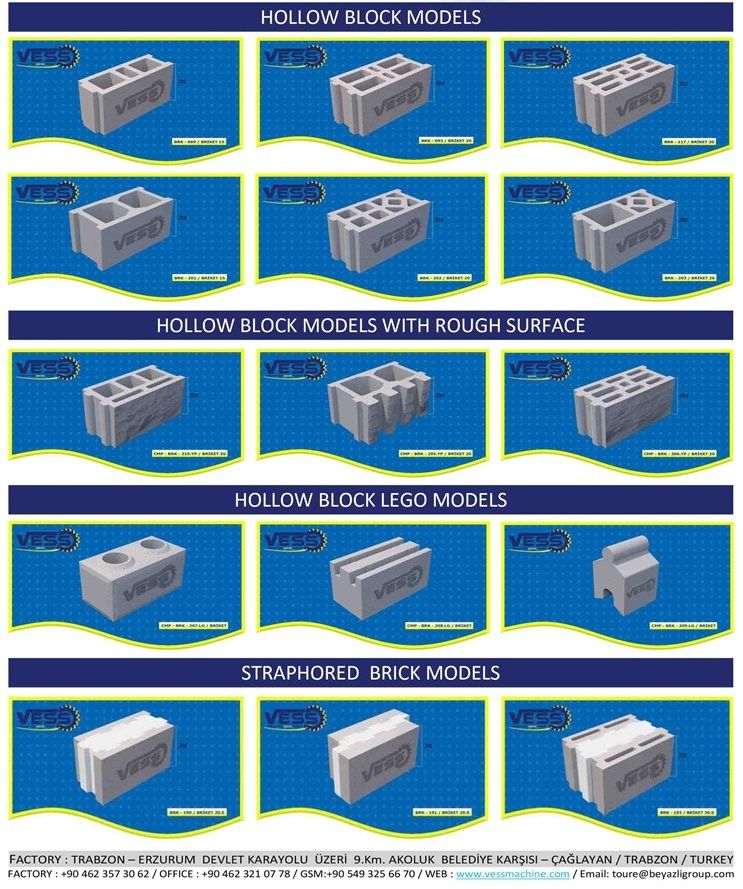

8 Popular Types of Hollow Concrete Blocks

- Stretcher Block: These blocks are commonly used in the main wall construction and are laid horizontally with their length parallel to the wall's length.

- Corner Block: Corner blocks are designed to be used at the corners of walls, providing a smooth and neat finishing point.

- Pillar Block: These blocks are utilized in constructing pillars or columns within a structure.

- Jamb Block: Jamb blocks are used to form the sides of door and window openings, providing a stable framework for installing doors and windows.

- Partition Block: Partition blocks are employed in non-load-bearing walls that divide the interior space of a building into rooms or sections.

- Lintel Block: Lintel blocks are placed horizontally above the door and window openings to support the load from the structure above.

- Frogged Brick Block: These blocks have a depression or groove (known as a "frog") on their top surface, which can be used for holding mortar or for better adhesion.

- Bullnose Block: Bullnose blocks have rounded edges, often used for creating smooth and decorative finishes on corners or edges of walls.

Each of these types serves a specific purpose in construction and contributes to the overall structural integrity, aesthetics, and functionality of the building.

You can visit our concrete block mold gallery for more details.

How To Choose Block Making Machine Price?

When you enter terms like "hollow block machine for sale" into a search engine like Google, you're likely to be inundated with millions of search results. This holds true whether you're searching for a "block machine price list" or specifically exploring the "solid block making machine price." In such a scenario, finding the optimal website and subsequently purchasing a machine that aligns with your requirements can prove to be a challenging task.

Before purchasing a concrete block machine, every customer should consider several important questions:

- Reliability and Quality: Is the machine dependable, sturdy, and robust enough to consistently produce high-quality blocks?

- Versatility: Does the machine possess all the necessary features to manufacture a variety of concrete block types?

- Pricing and Discounts: What are the associated costs, and are there any available discounts or promotional offers?

- Cost-Effective Alternatives: Are there other concrete block machines that offer comparable features at a more budget-friendly price?

Concrete blocks are manufactured in required shapes and sizes and these might be solid blocks or hollow blocks. A paver block is also a block made of the same concrete and used for paving the roadway or backyard of our houses. The machine used to produce these paving blocks is a little bit different from the concrete block machine. It is called paving block machine.

If you have sufficient and reliable answers to these questions, you will make the best choice.

According to our study, the hollow block making machine price in India or China is not very different from the price of other manufacturers in Turkey. The quality or features of these machines are sometimes not suitable for some countries in Asia or Africa regarding the differences in climate. Our company BEYAZLI GROUP manufactures concrete block machines not only for Turkey but also for all the countries over the world. Some features of our concrete block machines:

- Paving block, hollow block, solid block, and curbstones machines

- Premium quality machines with german equipment installed on the machine

- Reliable Machines

- Available in different capacities

- Available in different automation levels

- Robust Machines

- Best Quality Machines.

The Technology Used In The Concrete Block Machine

The technology used for the manufacture of our concrete block machine meets European standards. The technological part of the machines is generally similar to Siemens technologies because we are using Siemens equipment. The use of the latest technology on these concrete block machines has made a big difference in terms of quality.

The shape of the blocks or pavers depends on the choice of customers. The concrete block machine has the possibility to produce blocks with a size between 5 cm and 30 cm in height. The machine produces between 4 and 72 blocks in a single press. Our technology allows the machine to produce not only pavers but also different types of concrete blocks such as:

- The concrete hollow blocks (or bricks) like stretcher blocks, corner blocks, pillar blocks, jamb blocks, partition blocks, lintel blocks, frogged brick blocks, bullnose blocks

- Curbstones

- Standard Core-Fill Block

- Column Block

- Slump Block

- Retaining-Wall Block

- Grasscrete

- and the slabs for the construction of the buildings.

You can see our PRS1200 fully automatic machine in action. for more videos please visit Concrete Block Making Machine youtube channel.

This technology allows you to produce all these types of concrete blocks in different colors and patterns. If you are looking for a concrete block machine for sale, you can visit our products on the website. After purchasing the machine, we deliver three molds to the customer depending on his or her choice.

For more information about our concrete block making machines or to get a hollow block manufacturing business plan based on your machine and country, please contact us at below contact details.