Concrete Block Machine In Djibouti

Many companies are investing in Djibouti right now because it is one of the developing countries with good potential. Bess company is one of these companies that installed different types of concrete block machines in Djibouti.

Bess company has different types of concrete block machines with different capacities and automation levels. Depending on customer demands, we can offer different machines based on the project.

Bess company has already installed more than 350 machines in 32 countries. Some of these machines are more than ten years old right now and still working.

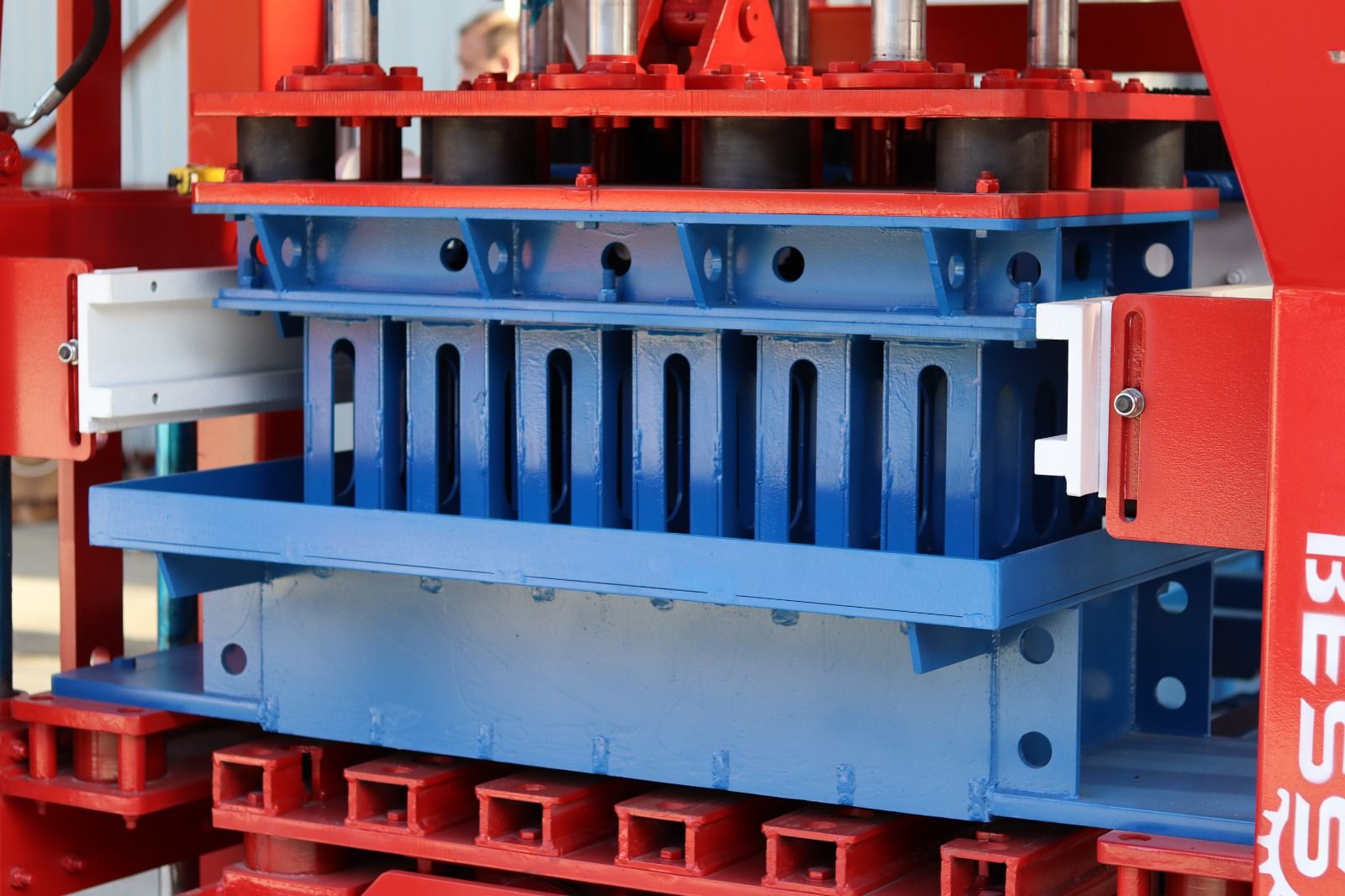

The first type of the block making machine Bess Company offers for Djibouti is PRS semi-automatic concrete block machines:

The PRS semi-automatic series need six workers for the whole plant. The mixing system is also semi-automatic. It means the operator controls the process of the concrete mixing. An operator with joysticks also controls the machine.

The PRS semi-automatic concrete block machines are available in 4 different capacities. The smallest machine can produce 4000 pieces of standard hollow blocks 20cm x 40cm x 20cm per shift. You need 1000 pallets if you are using the machine 8 hours a day. The same pallets are used again the next day after the blocks are collected.

The pallets are transported to the curing area by wheelbarrows in the semi-automatic machines. It means they are moved one by one by the workers.

The second type of the block making machine Bess Company offers for Djibouti is PRS automatic concrete block machines:

Totally four workers are needed for an automatic block making plant. One worker takes care of the mixing system. One worker operates the machine and another worker drives the forklift. The other worker takes care of collecting the blocks from the pallets. For more details please check brick making machine price and details.

The automatic concrete block machines for Djibouti are available in 4 different capacities. However, it is more logical to choose higher capacities if you choose automatic machines.

The table below shows block making machine price and capacity details:

Concrete Block Machine Price And Capacity For Djibouti |

||||

|

Machine Name |

Capacity Per Shift For Blocks |

Capacity Per Shift For Pavers |

Installation |

Price |

| PRS 400 | 4000 Pieces Of 20cmx40cmx20cm Blocks | 300 m2 Of Interlocking Paving Blocks | Free | 50.000 USD Full Set |

| PRS 600 | 6000 Pieces Of 20cmx40cmx20cm Blocks | 400 m2 Of Interlocking Paving Blocks | Free | 70.000 USD Full Set |

| PRS 800 | 8000 Pieces Of 20cmx40cmx20cm Blocks | 550 m2 Of Interlocking Paving Blocks | Free | 90.000 USD Full Set |

| PRS 1000 | 10000 Pieces Of 20cmx40cmx20cm Blocks | 700 m2 Of Interlocking Paving Blocks | Free | 110.000 USD Full Set |

To install these machines, you need to prepare your land. The total size of the land needs to be 2000 m2 or bigger. This land includes all the machine areas, including the machine section, curing area, block storage, and aggregate storage.

After we sign a contract with a customer, our technical team will prepare a plant layout based on your land dimensions and send it to the customer. The customer can prepare their land based on the drawings.

After your land is ready and the machine arrives at your plant, our technical team will come and install the machine for you. They will run test samples, train your operators on how to use the machine, do the maintenance, and change the mold. After everything is set, we will sign the guarantee papers and your guarantee starts from that day. Bess Concrete block machines have two years of guarantee.

Concrete block molds available for the concrete block machines:

By changing the mold, you can produce different shapes of concrete blocks. Bess concrete block machines can produce blocks with a height between 5cm to 30cm. There are almost 500 molds available for the Bess block making machines. Here is a list of the concrete block molds available.

1. Hollow blocks with different shapes and sizes.

2. Solid blocks with different shapes and widths

3. Paver blocks with different shapes and thicknesses

4. Different models of curbstones

5. Styrofoam concrete blocks with interlocking ability. These blocks are also known as polystyrene concrete blocks.

6. Roofgutters

7. Hollow floor blocks

8. Special purpose blocks

Bess company produces its own molds with premium quality. So, if you have a special shape in your mind you can send us the shape and design. We can manufacture your desired concrete block mold shape for you.

Conclusion

If you don't know which machine is the best for your plant or what capacity you need to choose you can contact our sales department. With more than 15 years of experience in this field of business, you can discuss your project details and they will suggest the best options for you. Bess company also provides free installation and commissioning when you buy the machine.

The pallets are transported to the curing area by wheelbarrows in the semi-automatic machines. It means they are moved one by one by the workers.