PRS400 block making machine

PRS 400 is a concrete block making machine From the PRS family. actually, it is the smallest member of the PRS family. The PRS name is driven from the pressing process that is used to produce concrete blocks. Bess has designed PRS block making machines and manufactures it using German brands and using cutting edge technology in its workshops.

Bess has started its international business in 2005 and up to now, it has installed more than 350 working plants in 32 countries. Bess is a well-known brand in the block making industry thanks to its premium quality block making machines, free installation services, and efficient after-sales system.

Consider that the PRS400 block making machine is a single-hopper machine, single-hopper machines are also called hollow block making machines, we have also prepared an article about hollow block making machines if you are interested to have further information about them.

The double hopper machines are mostly called paver block machines because the second hopper is used to produce colored paving blocks. We have prepared an article for paver block machines if you need to get further information.

PRS400 block making machine capacity

The PRS 400 block making machine can produce more than 400 shapes of concrete blocks by changing the molds. It can produce hollow blocks, solid blocks, curbstones, lawn blocks, and paving blocks. All you need to do is to change the mold to produce your desired blocks. Depending on the shape the capacity of the machine changes.

For smaller blocks, the capacity rises and for bigger blocks, the capacity drops. so how should we use a standard sizing system for this purpose?

The standard size of the concrete block that the capacity of the machine is explained with is a hollow block with the dimensions 20cm width x 40cm length x 20cm height.

The PRS 400 concrete block machine produces 4 pieces of these hollow blocks in one press and a total of 4000 pieces in 8 hours.

The table below shows more details about capacity.

| Block Type | capacity in one press | capacity in one shift |

| 20cm x 40cm x 20cm hollow block | 4 pieces | 4000 pieces |

| 15cm x 40cm x 20cm hollow block | 5 pieces | 5000 pieces |

| 10cm x 40cm x 20cm hollow block | 6 pieces | 6000 pieces |

| I-shape paving block | 12 pieces | 300 m² |

| rectangular paving block | 20 pieces | 400 m² |

| curbstone | 1 piece | 1000 pieces |

PRS400 block making machine types

The PRS400 block making machine is offered in two different types:

1. semi-automatic block making machine

2. automatic block making machine

Below you can see the production process of the PRS 400 semi-automatic block making machine

When the aggregates are mixed they form the mortar. the mortar is then delivered to the hopper of the block making machine.in both machines, the mixing system is done semi-automatically. it means that the aggregate, water, and cement are added to the mixer by pushing buttons. The operator keeps an eye on the process and controls how much of each material is needed to be added to the mixer.

the operation of the machine is also controlled by the operator. one operator is present in the control panel and controls the vibration, and pressing process. after this stage, the machines use different methods to deliver the pallets.

In the semi-automatic system, the pallets are delivered to the output of the machine and then delivered to the curing area by wheelbarrows. this is done one by one.

the next day when the blocks are ready, the operators collect the blocks and feed the pallet to the machine again.

in the automatic system, the pallets are put on top of each other for five times, then the forklift delivers the five pallets to the curing area. The next day when the blocks are dried they are delivered to the input of the machine by the forklift. Then the unloader robot separates the pallets and products are collected by a pneumatic robot. the pallet is then used for production again.

PRS400 block making machine technical information

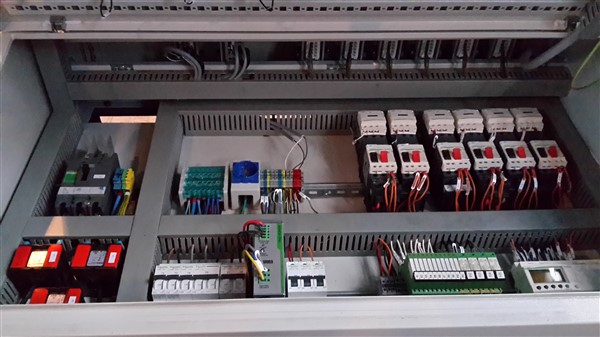

Bess only uses premium quality equipment on the machine. For the hydraulic system, we use the bosch-Rexroth Italian brand which produces the best parts for hydraulic systems. For the electric system and PLC, we use Siemens and Schneider brands. These parts mean the life span of the machine will be as long as possible and the maintenance time with be as short as possible.

Consider that Bess Block making machines are sturdy and in longterm use, they show a great performance. Thanks to its modern design the maintenance is also simple and takes only a few minutes.

The table below is a few technical specifications of the PRS 400 block making machine semi-automatic type. If you need further information or you can contact us anytime. our contact information is written at the end of this article.

| PRS400 Technical Specifications | |

| Production Capacity | 100 - 120 Pallets/Hour |

| Lower Vibrator Power | 2 x 5.5KW |

| Upper Vibrator Power | 2 x 0.75KW Optional |

| Hydraulic Tanks Capacity | 350 L |

| Hydraulic Pressure | 150 Bar |

| Hydraulic Motor Power | 5.5 KW |

| Pallet Dimensions | 100cm x 50cm x 4 cm |

| Min-Max Product Height | 5cm - 25cm |

you can also click to see the PRS400 automatic block making machine.

PRS400 block making machine price

Before we talk about the price we need to consider the factors that affect the price. the items below are the most important price factors of the PRS400 block making machine.

1. Automation level: choosing between semi-automatic and automatic will affect your price considerably. If you are living in a country with low labor costs and cheap land you can choose the semi-automatic version which is cheaper. it only requires two extra workers.

If you are living in a developed country where labor cost is high you would prefer to choose an automatic machine with a higher capacity.

2. Pallets: the number of pallets you choose to buy with the machine will affect the total cost of the plant. Customers usually prefer to produce them locally to prevent extra transportation costs. You normally need 1000 pallets to operate your plant for one 8-hour shift per day.

3. Molds: the number of molds you choose for your machine will change the total price of the plant. Bess produces its own concrete molds. We use ST52 metal sheets to produce our concrete block molds and we cut them with CNC machines to have the maximum accuracy. the hardening process is also done twice to have a maximum life span for the molds. Bess concrete block molds have an 80.000 press guarantee.

4. Extra equipment chooses for the machine: this can be pallet brush, product brush, extra cement silo, or other optional equipment.

For further information, you can contact our English department.