Brick Making Machine Price

If you are interested in starting your concrete brick manufacturing plant, you need to learn the basics of this business. The automatic brick making machine price generally depends on the factors below:

1. The automation level of the brick making machine.

2. The capacity of the brick making machine.

3. The country of origin.

4. Different pieces of equipment ordered with the machine.

5. The number of molds ordered with the machine

6. The distance of your plant with the manufacturing country.

We have included the brick making machine price list below but to make sure what you are investing in, you need to learn the machine before we talk about the prices. In this article, each topic is explained briefly, if you need further information please contact us.

What Is Brick Making Machine?

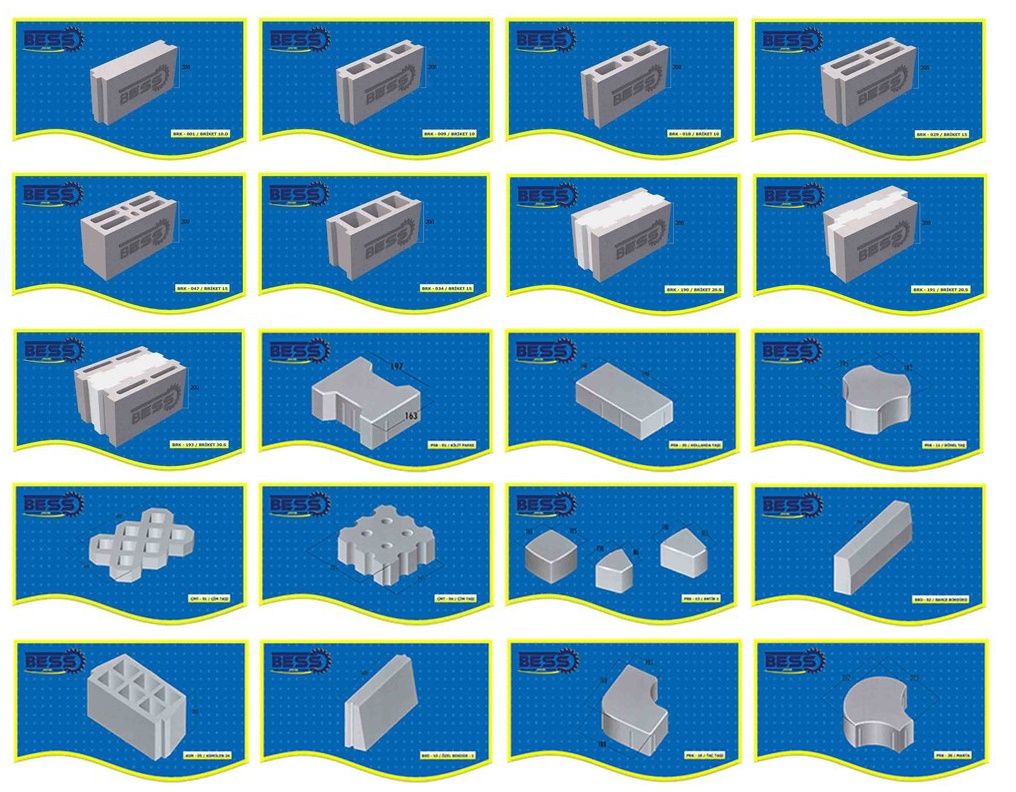

A brick making machine is a machine that produces concrete bricks. Concrete bricks are mostly used in the construction industry to build the walls, pave the surface, and to separate roads from sidewalks. This means a brick making machine can produce different types of concrete bricks. The name ''concrete brick'' includes different shapes of the blocks.

The list below shows some of the concrete bricks:

1. Hollow concrete blocks and solid concrete blocks

2. Paving blocks (also called pavers)

3. Styrofoam blocks

4. Curbstones

5. Interlocking blocks of all the types above

6. Lego blocks

Based on the products that the machine produces there are different names for the machine. If you hear someone call the machine a concrete block making machine or a hollow block making machine this means it is almost the same machine with some extra details and equipment with their machine. Read the articles related to them to find out more.

Bess concrete brick machines can produce 100 -120 pallets in one hour. The number of products on each pallet depends on the capacity of your machine and the size of the products. This is one of the major factors for the automatic brick making machine price.

For example, a size four machine can produce 4 pieces of standard concrete blocks (a hollow block with the dimensions 20cm x 40cm x 20cm) in one press however it can produce 6 pieces of 15cm blocks in one press.

To produce these blocks, all you need to do is to order the mold with the shapes and dimensions that you want and install it on the machine. To see our mold samples, you can visit our mold gallery as well. In the brick making machine, the pressure and vibration are applied to the molds at the same time to produce blocks.

How Does Automatic Brick Making Machine Work?

An automatic brick making machine is a machine that produces concrete bricks automatically.

The production process of the brick making machine is explained below:

1. First, we fill the aggregate hoppers with aggregate and fill the cement silo with powdered cement

2. The machine automatically weighs the cement, the aggregate, and the water. They are all added to the mixer.

3. The mixer mixes all of them together to produce a mortar that is suitable for concrete brick production.

4. The mortar is then delivered to the hopper of the machine.

5. The machine automatically produces the concrete blocks with the help of an operator.

6. The pallets are then delivered to the curing area and will be there for 24 hours to dry.

7. The pallets are then delivered to the unloader robot to collect the products from them so they will be ready for production again.

The process explained is the production process of the automatic brick making machine. Below is also the animation video of the process. You can also visit the BESS machine EN youtube channel for more videos and references.

The single-hopper brick making machines are usually called hollow block machines. Consider that this is a single-hopper brick making machine.

The double-hopper brick making machines are usually called paver block machines. You can see their prices in paver block making machine price.

Consider that double hopper machines have the advantage of producing double-layer paving blocks with different colors.

Automatic Brick Making Machine Price 2022

With more than 15 years of experience and more than 350 working plants, Bess company produces different types of brick making machines with different automation levels. Consider that all the pieces of equipment we use on the hydraulic and electric panels of the machines are German brands.

Below you can see a few samples of our machines including the price.

| Machine Name | Capacity (blocks) | Capacity (pavers) | Installation & commissioning | price |

| PRS 400 AUTOMATIC | 4.000 BLOCKS | 300M² | INCLUDED | 51120 USD |

| PRS 402 AUTOMATIC | 4.000 BLOCKS | 300M² | INCLUDED | 58780 USD |

| PRS 600 AUTOMATIC | 6.000 BLOCKS | 450M² | INCLUDED | 60150 USD |

| PRS 602 AUTOMATIC | 6.000 BLOCKS | 450M² | INCLUDED | 65980 USD |

| PRS 802 AUTOMATIC | 8.000 BLOCKS | 550M² | INCLUDED | 78500 USD |

For more details, you can visit Bess Products.

Automatic Brick Making Machine In Your Country

As you can see above, the prices of automatic machines are a little bit high compared to semi-automatic types. Each machine has its pros and cons, As someone with enough experience in this field I have a recommendation for you:

1. If you are living in a developed country like Canada, United Kingdom, USA, Australia, New Zealand, Saudi Arabia, Egypt, Norway, Denmark, Hungary, Poland, Serbia, Kosovo, or other countries where labor cost is high, you need to choose automatic and fully automatic machines for your plant. Automatic brick making machines may increase your investment value in the beginning but you will need fewer workers for your plant. this will result in more profit in the long term.

2. If you are living in a developing country like Uganda, Ghana, Kenya, Gabon, Somalia, or other countries with low labor costs, I recommend you to buy a semi-automatic brick making machine which is much cheaper than automatic types. In this way, you can start your plant with a lower budget and in the future, you can also upgrade your machine or buy a second semi-automatic machine.

Bess company also prepares your special blocks business plan free of charge. You can also contact our English department for further information.