PRS400 Block Making Machine And Chinese Block Making Machines Differences

To compare the block making machines together first, we need to know the standard factors that are used in these machines. the standards below help you understand the comparison more deeply.

The first thing we need to know is the capacity of the block making machine. The capacity of the machine is determined by the number of standard 20cm x 40cm x 20cm blocks that the machine can produce in one press.

The PRS400 can produce 4 standard hollow blocks in one press so the comparison should be with the Chinese machines in the same capacity.

The second factor is the automation system. The semi-automatic means that after the pallets are produced, they are delivered to the curing area by pallet trolleys.

There is also an automatic version in which forklift is used to deliver the pallets. This system is not included in this article. If you need more information about these machines you can read the article Automatic concrete block making machine price.

To compare the semi-automatic machines we need to consider each section separately. We will compare the two machines in the parts below and explain them one by one.

Aggregate hopper, conveyor belt, mixer, machine, the main block making machine, hydraulic system, Vibration system, Electrical panel, mold, and products.

Aggregate Hopper

Bess PRS400 aggregate hopper:

The aggregate hopper is where you store aggregate like sand, stone dust, gravel, fly ash, or other types of aggregates.

Bess offers different types of aggregate hoppers with different capacities based on customer demand. To compare the similar ones we chose a double-compartment aggregate hopper for the PRs 400 semi-automatic block making machine.

The chassis of the aggregate hopper is manufactured according to ISO 9001 standards.

The discharge system operates by vibrators installed on the cover of the aggregate hopper. The vibrator power is 750w.

For the body of the mixer, we use 5mm metal sheets so the customers have a lifetime aggregate hopper.

The main motor installed on the conveyor belt is 2.2kW coupled to a gearbox reducer.

Chinese aggregate hopper:

The Chinese companies use 3mm metal sheets for the body of the aggregate hopper. This item is mostly optional for their machines because most of them install a small hopper on top of the mixer instead of this type of hopper. As optional you can choose a single, double, or triple-compartment aggregate hopper for the machine. The picture below is a sample picture of the three-compartment aggregate hopper.

The capacity of the aggregate hopper is 1.2 m³ and discharge is with vibrators as well. the vibrator power is 750W Chinese brand.

The main motor installed on the conveyor belt is 1.1kW and connected with belts. The belt system is not very reliable.

The table below shows the comparison between two aggregate hoppers:

| aggregate hopper comparison | Bess PRS400 aggregate hopper | Chinese brand aggregate hopper |

| capacity | 1.2m³ | 1.2m³ |

| metal sheet thickness | 5mm | 3mm |

| vibrator | 750W Turkish Brand | 750W Chinese brand |

| conveyor belt motor | 2.2 kW | 1.1kW |

| motor connection | Gearbox | Single Belt |

Conveyor belt

The conveyor belt is the equipment that connects the hopper to the mixer and the mixer to the machine. The raw material and the mortar are transferred through the conveyor belts. The conveyor belt has different parts: the main chassis, the rollers, the belt, the electrical motor, and the reducer.

Bess conveyor belts:

For the main chassis, Bess uses a 40 x 80 x 30mm profile, for the rollers we use French bearings. One of the best in the world.

The electric motor that is installed on the conveyor belt is 2.2 kW and it's coupled to a gearbox reducer. this means that there is no belt used to connect the motor to the conveyor belt.

The belt that transfers the materials is 8mm thick and Italian. optionally the customer can order the belt with an upper cover.

Chinese Conveyor Belts:

The length of the Chinese conveyor belt for their machine is a total of 6 meters. The electrical motor used for this conveyor is 1.1 kW and Chinese brand bearings are used in the rollers.

The connection system between the conveyor belt and the motor is with a single belt.

comparison:

The problem with the single connecting belt is that when it is broken, your conveyor belt will stop working, and because of the weight of the material on it, it will slip backward pouring all the aggregate or mortar on the ground. the solution to this problem is using a coupled electromotor and reducer. If anything happens to the motor, the gearbox will lock the conveyor belt and prevent the slip.

Since the bearings are exposed to different weather conditions they should be high quality and well protected against humidity. If the rollers stuck they will damage the main belt so it is necessary to choose the right rollers.

The table shows the comparison briefly:

| Conveyor Belt | Bess PRS400 Block Making Machine | Chinese Block Making Machine |

| Length | 9 meters | 6 meters |

| Motor | 2.2kW Turkish Brand | 1.1 kW Chinese Brand |

| Connection | motor and Reducer | Single Belt |

| Number Of Connection Belts | - | Single Belt |

| Conveyor Thickness | 10mm | 8mm |

| Bearings | French Brand | Chinese Brand |

| Angle | Standard | Too High |

Concrete Mixer

The concrete mixer used in the PRS400 block making machine:

the capacity of the mortar mixer used for the PRS400 block making machine is 0.25 m³. The electrical motor used in the mixer is an 11kw-3phase Turkish motor suitable for this purpose. The motor is connected to a gearbox reducer with belts.

The brand of the reducer we use is also Turkish. To control the electric motor there is an electrical panel installed next to the mixer so the operator can control it. All the electrical equipment used in the electrical panel are German brands. The motor is protected with overcurrent relays as well.

For the body of the mixers, Bess uses Premium quality 10mm metal sheets. The inner side of the mixer is also reinforced with 10mm abrasion metal sheets to protect the main body of the mixer for long-term use. Bess also installs wearing metal sheets on the mixing arms with bolts and nuts. You can replace them easily when they are worn out.

The discharge system of the mixer is pneumatic. this system is operated with the command of the operator by pushing the buttons on the control panel.

|

|

The concrete mixer used in Chinese block making machines:

For the mixer, a 7.5 kW motor is used. It is connected to a reducer with belts. The brand of the electric motor and reducer is mostly Chinese as well.

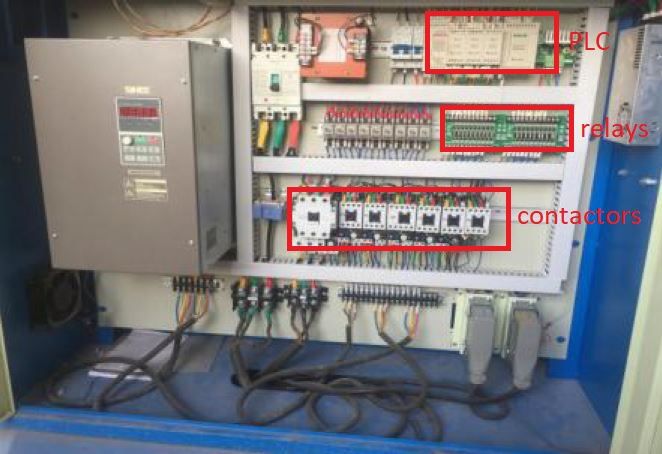

The Chinese use the German brand PLC as the main control system but the relay and wires are Chinese brands. Consider that most of the time when a fault happens the main problem is not with the PLC, but it is with the relays.

There are no protection relays to protect the motor in Chinese electric panels. This is to reduce the total price and sell extra motors to the customer in the future. There is no PLC in the electrical panel of the mixer as well.

As you can see there are no ducts, protection relays, or earthing installed on the panel. It is also very dangerous for the technician to do maintenance on these panels because the wires are not covered in ducts and terminals are not in the standard place.

For the body of the mixer, the Chinese block making machines use an 8mm metal sheet without any abrasion sheets. The output of the mixer is also operated by hand. the picture below shows a sample picture of the mixer that is offered with most Chinese concrete block making machines.

The table below shows the differences altogether:

| Mixer Comparison | Bess PRS400 | Chinese brand |

| Total Metal Sheet Thickness | 20 mm | 8 mm |

| Motor Power | 11 kW | 7.5 kW |

| Capacity | 0.25 m³ | 0.25 m³ |

| Discharge Type | Pneumatic | Manual |

| PLC Brand | German Brand | No PLC |

| Other Electrical Equipment | German Brand | Chinese Brand |

| motor brand | Turkish | Chinese |

The Block Making Machine

The main block making machine consists of different parts like the hydraulic system, molds, and electrical panel. Those are compared in the next parts, in this part, we are going to compare the body and structure of the two machines.

Consider that this is very important if you are planning to use the machine for the long term. If the structure is weak it will crack in the future and there will be a lot of loose parts in your machine. it will also considerably affect the quality of your concrete blocks.

|

Comparison:

| Main Block Making Machine | Bess PRS400 Block Machine | Chinese Block Making Machine |

|

Body Dimensions (L x W x H) |

550cm x 200cm x 250cm | 390cm x 138cm x 220cm |

| Weight | 7800 kg | 3000kg |

| Pallet Size | 115cmx 50cm x 4cm | 85cm x 55cm x 2cm |

| Number Of Protecting Shafts | 6 | 2 |

| Guarantee | 2 years | 1 year |

The protecting shafts are very important to maximize the life of the block making machine. As you can see below these shafts are located in special places to guide

the movement of the molds and pistons in the correct way.

Hydraulic System

The hydraulic system had different functions in the block making machines. there are 5 different functions of the hydraulic system.

1. Opening and closing the mortar hopper of the block making machine.

2. Moving the mortar shaking grate forward and backward.

3. Moving the upper mold upward and downward.

4. Moving the button mold upward and downward.

5. Pull the new empty pallet to the machine.

Because the hydraulic pistons bear a lot of pressure and operate the heaviest parts of the machine, they need to be premium quality so they won't break easily. The working pressure of the machine also needs to be at least 120 bars to produce high-quality concrete blocks.

The different parts of the hydraulic system are listed below:

1. Hydraulic tank

2. Hydraulic pomp

3. Hydraulic pistons

4. Hydraulic valves

4. Connecting equipment

Bess PRS400 Block making machine Hydraulic system

The hydraulic tank capacity that we use is 350 liters,

we have 7 hydraulic pistons installed on the main PRS400 block making machine. One piston is for opening and closing the mortar hopper cover. two pistons move the mortar shaking the grate back and forth. another piston moves the upper mold up and down. Two pistons operate the down mold. finally, one more piston pulls the new pallet to the machine for the pressing process.

|

|

The Brands we use for the PRS400 semi-automatic block making machine are all Turkish brands. For automatic machines, we use Italian brands.

The hydraulic pressure that the PRS400 semi-automatic concrete block machine operates with is between 150 to 200 bar. This pressure is set based on the customer's country.

Bess also uses specially designed hydraulic pistons with shock absorbers so the pistons have a maximum life expectancy and the shocks won't hurt the piston or chassis in the long term.

Chinese block making machine Hydraulic system

The hydraulic system used for the Chinese brand block making machine has a tank capacity of 350 liters. It runs with 250 liters of oil. The hydraulic pistons used in the machine are also normal Chinese brands without a shock absorber.

The hydraulic valves installed on the hydraulic system are Taiwanese brands or famous Chinese brands. the number of hydraulic valves used on the machine is 6.

Comparison:

The two Hydraulic systems are so different to compare. The table below compares the two systems in a few aspects.

| Hydraulic System | Bess PRS400 Block Machine | Chinese Brand Block Making Machine |

| Number Of Pistons | 6 | 6 |

| Type Of Pistons | Special Design with shock absorber | normal pistons |

| Hydraulic Pressure | 150 - 200 Bar Adjustable | 160 Bar |

| Hydraulic Tank Capacity | 350 L | 350L |

|

Hydraulic Valves |

6 | 6 |

| Hydraulic Valve Brand | Turkish famous brand | Chinese famous brand |

| Maintenance | Easy | Difficult |

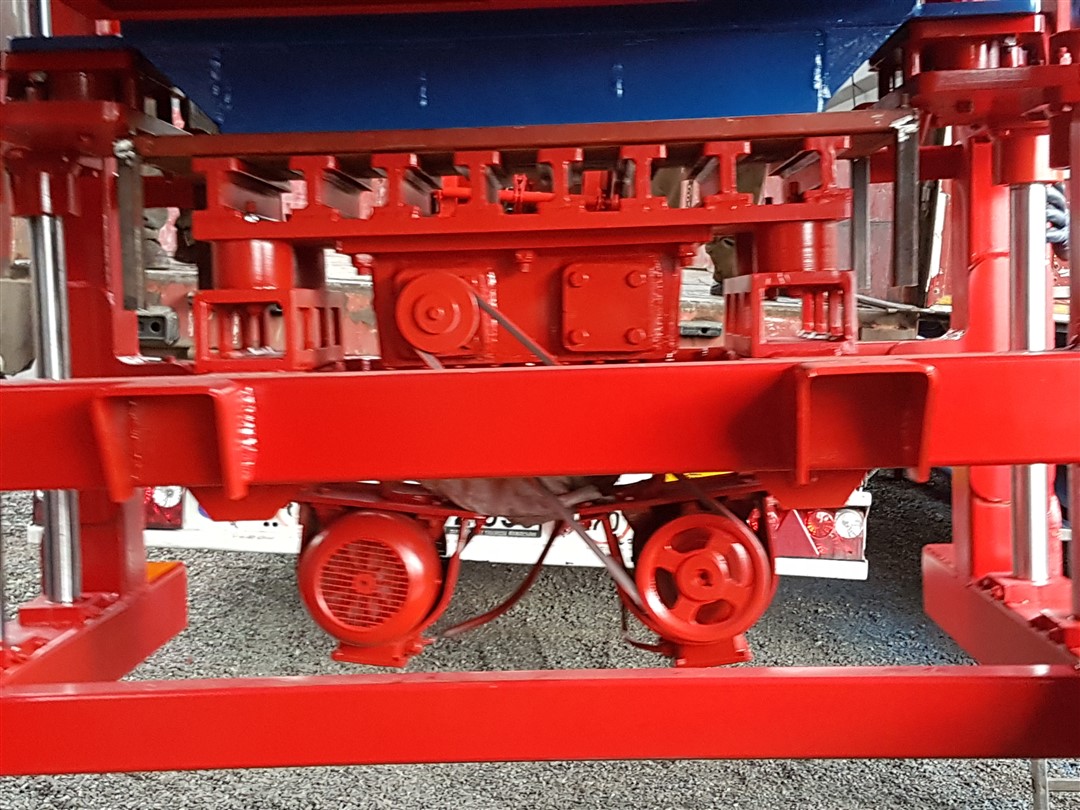

Vibration System

The vibration system is the necessary equipment to produce high-quality blocks because it considerably improves the compression of the blocks. The vibration system is installed on the vibration table under the pallet.

Bess PRS400 vibration system.

Bess uses 2x5.5 kW motors for the main vibration and also 2x0.75kW motors for the upper vibration. The upper vibration is optional in the PRS400 semi-automatic block making machine. The brand of the motors used for the vibration table is siemens brand, Bess also uses electrical drivers to change the frequency of the vibration motors.

This means the vibration will have a smoother start, in the beginning, preventing damage to the machine and a more intense vibration force due to the higher frequency.

There are also rubber shock absorbers installed on the machine to prevent the vibration force to damage the main chassis of the machine.

Chinese vibration system for the block making machine:

The Chinese use famous Chinese brand motors or siemens motors for vibration. If you choose the siemens brand it will be a price difference of about 1500 USD. No drivers are used to change the frequency of the vibration system and no shock absorbers are used to absorb the vibration force. It is directly transferred to the chassis of the machine. The motors used as the vibration system are 2X5.5kW and there are no upper vibrators available.

Vibration force comparison:

| Vibration Comparison | Bess PRS400 | Chinese Block Machine |

| Bottom Vibration | 2 x 5.5kW | 2 x 5.5kW |

| Upper Vibration | 2 x 0.75Kw | X |

| connection type | Driver | Contactor |

| Driver brand | Siemens | X |

| Frequency | 30 Hz - 100 Hz | 50 Hz |

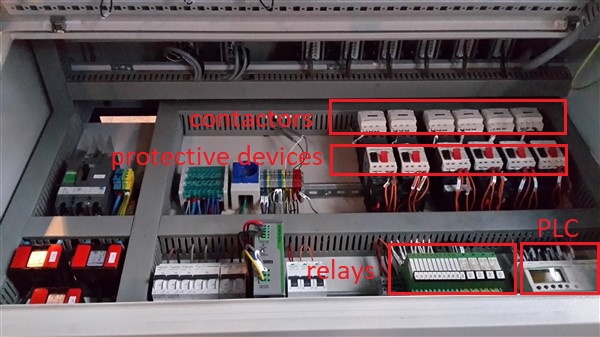

Electrical Panel

There are different control panels in the concrete block making machine. One electrical panel is normally installed next to the mixer for controlling the mixer and one main panel is installed next to the machine to control the machine. Since all the parts are almost the same we only discuss the main electrical panel installed on the machine.

The main electrical panel is the brain of every machine. All the different commands are sent by the electrical panel of the machine when a button is pushed.

The electrical panel has lots of equipment installed on it with a lot of details. We will compare both machines in the aspects below:

1. The main PLC

2. the contactors

3. the protecting devices

4. wiring

The PRS400 concrete block machine electrical panel:

the total power consumption of the main concrete block machine without the mixer and conveyor belts is 18 kW. All the motors installed on Bess block machines are protected By overcurrent relays. The main PLC is a German brand, and it is also protected by relays. The contactors used to operate the machine are all german brands as well.

A Turkish brand wire is used for wiring the electrical panel. To connect the wired to the terminal Bess uses wire ferrules to make sure the wire is well connected to the terminal.

Chinese concrete block machine electrical panel:

The total power consumption of the Chinese block making machine is 10.95 kW. As seen in the pictures the motors are directly connected to the contactors without any overcurrent protection relay. this means that if something goes wrong with the machine either the electrical motor or the contactor will burn.

The PLC brand is either a Chinese brand or a German brand depending on customer order but other electrical pieces of equipment are Chinese.

comparison:

The table below shows the differences between the two machines:

| Electrical panel equipment | Bess PRS400 Block machine | Chinese Brand |

| Number Of Contactors | 6 | 6 |

| Contactor Brand | Schneider | Chinese |

| Overcurrent Relays | 6 | X |

| Overcurrent Relay Brand | Schneider | X |

| PLC | Schneider | Chinese |

Concrete Block Mold

To produce the desired shapes of concrete blocks you need concrete block molds. These molds are produced in different shapes so the machine can produce hollow blocks, solid blocks, paving blocks, and curbstones. The concrete block mold is produced from different types of metal in different countries.

Concrete block molds have 2 different parts, the upper mold also called the male mold and the down mold also called the female mold.

The mold manufacturing process is a very accurate process. each micrometer is considered to produce the molds because they should fit each other smoothly.

Bess concrete block mold

Bess uses ST52 structural metal sheets to produce their molds.

you may wonder what is structural steel and what is the difference between mild steel and structural steel. here is the difference:

They are both strong and ductile. But, it should be mentioned that the main difference between mild and structural steel is that structural steels are stiffer in order to carry higher loads without needless sagging.

The process of cutting the steel sheets is done with CNC machines to be more accurate. The hardening process of the mold is also done twice to have more strength under pressure. the hardening process guarantees the long life of concrete block molds.

Bess guarantees its molds for 80.000 presses. The whole process of mold manufacturing takes between 14 to 21 days.

Chinese concrete block molds:

Chinese molds are made of reinforced steel suitable for molding. they are cut with CNC machines using wire cutters instead of the torch cutting process. The whole process of producing the mold takes one week and the hardening process is done once.

Comparison Between concrete block molds:

| Concrete block mold | Bess PRS400 Concrete block machine | Chinese block making machine |

| type of steel | ST52 | Reinforced Steel |

| Cutting system | CNC with torch | CNC with wire |

| hardening process | 2 times | 1 time |

Products

The product quality depends on different items. The first factor is raw material quality, cement quality, and water quality of the customer site. these items are different from one country to another. There is nothing that can be done about this item.

The second factor is the pressing force. To have better quality concrete blocks you need to have a high-pressure hydraulic system. if the blocks are not compressed hard enough they won't tolerate the pressure applied to them and they will crack or break when pressure is applied.

The second factor is vibration. The vibration is applied to the mold at the same time as the pressing process to guarantee a more compressed product. The vibration force is produced with vibrator motors. depending on their power and working mechanism their vibration force is measured.

product comparison between Chinese machines and PRS400 block making machines:

the hydraulic force and vibration force applied to the blocks are different from each other so the product compression will be different for sure.

If you don't have experience in this field the first look at both of the products will be the same. But if you send the blocks to the laboratory for tests, the results will be so different. The breaking point of the blocks produced by the PRS400 brick making machine is much higher than the Chinese product.

In most developed countries, the government has standards for the breaking point of the blocks. in most cases, the blocks produced by our rivals from china don't pass the test and they are under standard so the government doesn't let their citizens buy such machines.

Price

The price of the block making machines is different due to the quality difference they have. Consider that the lower price may look appealing at first but the price/quality factor is very important. here is a question for you before we start the price comparison

Why do mechanics never buy cheap tools and always buy tools made of high-quality raw materials and high-quality machining processes?

It is because a ten 10-dollar wrench may work for 6 months But a 30-dollar wrench lasts for 10 years or even more. I am sure you have a tool in your toolbox that you have had for many years and still using it.

The price comparison of the PRS400 block making machine and the Chinese block making machine

| Item | PRS400 Block Making Machine | Chinese Block Making Machine |

| Batching system | 15.000 USD | 9.000 USD |

| Machine system | 29.500 USD | 17.000 USD |

| Total price | 44.500 USD | 26.000 USD |

Conclusion

choosing the right machine for your business is very important. Because you are investing in the machine and expect to earn money from it. Maybe both machines look the same at the first sight but when you dig deeper and do a more precise investigation you can see that all the parts of the machine are different.

Choosing the right machine means that you need to choose a machine with the features below

1. A machine that is designed to work for long term.

2. A machine that can work 24/7 without any special problems.

3. A machine that is designed to work in different weather conditions.

4. A machine that can produce different shapes by changing the mold.

5. A machine that if you want to sell and buy a bigger machine you can sell second hand with a good price

6. A machine that has spare parts available in every market.

If you still have more questions or you need a quotation you can contact us anytime.