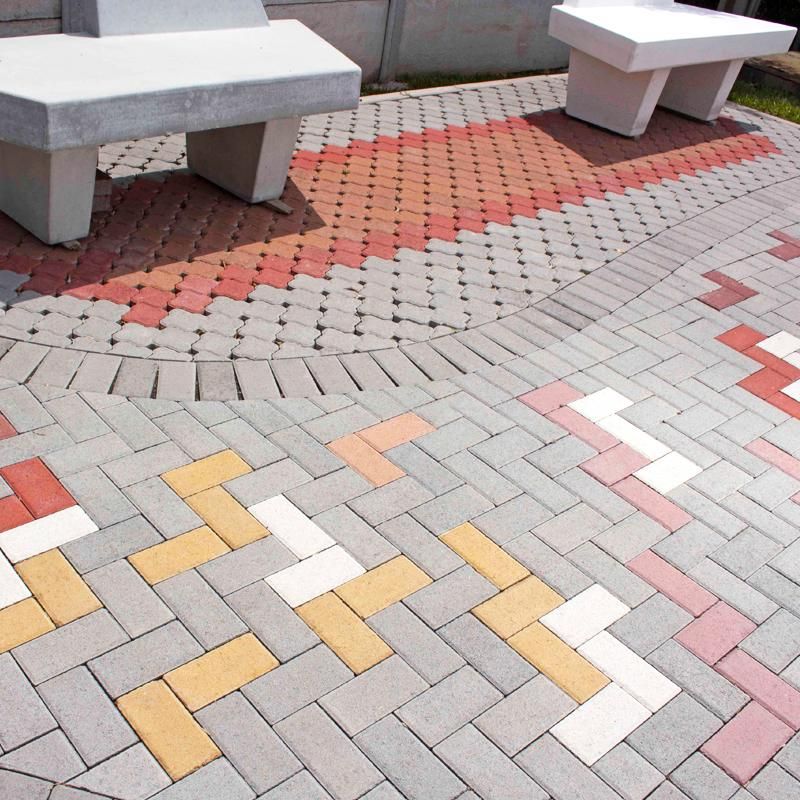

Paver Block Benefits

Paver blocks are popular because they offer several benefits over other traditional flooring options. Some of these benefits include:

-

Durability: Paver blocks are made of concrete or brick, which are both durable materials that can withstand heavy foot traffic and extreme weather conditions.

-

Aesthetics: Paver blocks come in a wide variety of shapes, sizes, and colors, which allows for a lot of creativity in designing outdoor spaces and creating unique patterns and designs.

-

Versatility: Paver blocks can be used for a variety of applications, including patios, walkways, driveways, and pool decks.

- Easy maintenance: Paver blocks are relatively low-maintenance and can be easily cleaned with a hose and broom.

- Cost-effective: Paver blocks are an affordable flooring option compared to other materials, especially if you install them yourself.

How To lay Paving Blocks

Paver blocks are produced in different shapes, thicknesses, and colors. The paving blocks are produced in a way so that interlock each other. This means they lock each other and hold each other and won’t lose their beauty so easily.

Laying paving blocks is a relatively straightforward process that can be done by anyone with basic DIY skills. Here are the steps to follow for laying paving blocks:

-

Prepare the base: Excavate the area where the paving blocks will be laid, removing any grass or vegetation and leveling the surface. Then, add a layer of crushed stone and compact it to create a solid base.

-

Mark the layout: Use a string line and pegs to mark the perimeter of the area where the paving blocks will be laid, and then use a straight edge and level to mark a straight line across the surface of the base material.

-

Install the edging: Install concrete or plastic edging around the perimeter of the paving area to contain the blocks and prevent them from shifting.

-

Apply a layer of sand: Spread a layer of coarse sand over the compacted base material, and use a straight edge to level it.

-

Lay the blocks: Start laying the paving blocks along one edge of the area, using a rubber mallet to tap them into place. Work your way across the area, keeping the blocks level and making any necessary cuts with a masonry saw.

-

Fill in the gaps: Use fine sand to fill in the gaps between the paving blocks, using a broom to sweep them into the joints.

-

Compact the sand: Use a plate compactor to compact the sand and stabilize the paving blocks.

-

Clean up: Remove any excess sand or debris from the surface of the paving blocks and enjoy your newly-laid paver patio or walkway.

Note: For larger paving projects, consider hiring a professional contractor to ensure the job is done properly and to your satisfaction.

Usually, for the places with a normal load on the paving blocks, we use 60mm pavers, and for the areas with a heavy load, we use 80mm paving blocks.

With the advance of technology these days, paving blocks are produced in double layers with different colors. These days you can see different shapes of them everywhere.

Paver Block Machine

If you want to produce pavers, you need a paver block machine. Paver block machines are produced in different shapes, capacities, and automation levels.

These machines are categorized as concrete block making machines.

There are small manual or semi-automatic paver block machines and there are fully automatic paving block machines as well.

Note that high-quality paver block machines also can produce hollow blocks, solid blocks, Styrofoam concrete blocks, curbstones, roof gutters, and almost 500 different shapes.

If the machine is a single hopper machine it is called a hollow block machine.

But If the machine is a double-hopper machine it can produce double-layer paving blocks so it is called a paver block machine.

You can also produce paving blocks with a hollow block machine but the problem is if you want to produce them with different colors you need to apply the color to the whole block, But in double hopper machines, the color is applied only to the top layer of the block.

This is also true about the surface quality of the paving blocks. If you want to use finer material to produce smooth surfaces you will need to apply it to the whole block in single-hopper machines but in double-hopper machines, the finer material is only applied to the top layer of the paving blocks.

Based on your project you can choose different machines. Below are some special features that you might want to know since it affects the paver block machine price.

Automatic Aggregate Weighing System:

Thanks to the aggregate weighing system your concrete ratio will always stay the same. This guarantees the final quality of the blocks. In this way, your product quality will always be the same and you won't lose your customers. To have an automatic weighing system you need to have cement silos, a water system connected to the automation system, aggregate hoppers, and weighing convert belts.

Second Mixer For The Color:

Some people prefer to have a second mixer for the color so the color won't be mixed in the same mixer. For this system, you will need 2 extra conveyor belts.

Second Hopper:

As discussed before, the single hopper only produces single-layer pavers whereas the double-hopper machine can produce double-layer pavers.

Loader And Unloader Robots:

Loader and unloader robots are very important systems in these machines.

If you don't use loader and unloader robots your machine is a semi-automatic machine, but if you use these robots your machine is an automatic machine.

In semi-Automatic paver block machines, handcarts are used to transport the pallets to the curing area one by one.

In automatic paver block machines first, the loader robot stacks 5 pallets on top of each other and then a forklift is used to transport the pallets to the curing area.

When the products are dried the forklift transports them to the back of the machine where the unloader robot is. The unloader robot separates the pallets and the products are collected from the surface of the pallets. The pallet again goes to the machine for more production.

Pallets:

Pallets are used in the production line. You can buy them from the manufacturing company or you can manufacture them locally. Mostly it is preferred to be produced locally because it will be cheaper. Bess is open to both options, if you choose to produce them locally Bess provides a few sample pallets also with technical drawings so you can easily produce them. For example, recently we sold a machine to Accra Ghana and the customer decided to produce the pallets himself. Further details: ''what concrete block making machine is the best choice for Ghana?''

Paving Block Machine Price 2023

The paver block machine price depends on different factors that are discussed above. The table below represents the paver block machine price based on the model and automation level.

Paver Block Machine Prices 2023

|

|||

Machine name |

Hopper Details |

Automation |

price |

| Vess Eco 4.1 | Single-Hopper | Semi-Automatic | 49.950 USD |

| PRS 600 | Single-Hopper | Semi-Automatic | 76.980 USD |

| PRS 602 | Double-Hopper | Semi-Automatic | 87.490 USD |

| PRS 800 | Single-Hopper | Automatic | 96.110 USD |

| PRS 802 | Double-Hopper | Automatic | 101.589 USD |

| COMPACT ELEGANCE | Single-Hopper | Automatic | 120.590 USD |

Note 1: You can click on the names of the machines to see the full details.

Note 2: The compact series are two machines in one. They are both block making machines and concrete batching plants.

Note 3: If you need a quotation or a proforma invoice you can contact us anytime. Our contact details are provided at the end of this article.

Note4: If you need further information and price about both hollow block machines and paving block machines you can read the article ''Brick Making Machine''.

Conclusion

If you don't know which paver block machine is the best option for you, you can contact us for further information. Our sales departments are experienced in this field and they can offer different options to you based on your project budget and project needs.

Bess also provides different layouts based on your land dimensions and your desired capacity. You can watch the videos of some of our sample machines on the Bess Machine EN youtube channel.